Key Advantages to Emphasize for Food Wrap PVC Compounds

1. Safety & Regulatory Compliance: The Non-Negotiable Priority

This is your number one selling point. Lead with this unequivocally.

-

FDA Compliance / EU Food Contact Regulation (EC) 1935/2004: State prominently that your compounds are fully compliant with stringent international food safety standards. This is the first box a manufacturer must check.

-

Non-Toxicity & Purity: Emphasize that your formulations are free of heavy metals (like Lead, Cadmium), restricted phthalates, and other harmful substances. Use terms like “Food-Grade” and “Food-Safe”.

-

Certifications: If you have specific certifications from regulatory bodies (like the FDA) or independent labs, mention them explicitly. This provides tangible proof and builds immediate trust.

2. Superior Clarity & Aesthetics

Food marketing relies on presentation.

-

Crystal Clarity: Highlight the excellent optical clarity of the film produced, allowing the food’s natural appearance to be visible, which is a key consumer preference.

-

Low Haze & High Gloss: Mention these specific properties that contribute to a premium look and feel on the supermarket shelf.

3. Excellent Performance & Functionality

The wrap must perform its job effectively.

-

High Flexibility & Strength: As a soft PVC, the film must be highly flexible and tough, resisting tearing during handling and use. This comes from your specialized plasticizer system.

-

Strong Cling: Emphasize that your compound formulation promotes excellent self-adhesion (cling) without being overly sticky, ensuring a tight seal around food containers.

-

Good Permeability Balance: The compound should allow the wrap to have a suitable balance of gas (oxygen) and moisture transmission to help maintain food freshness.

4. Manufacturing Efficiency

Appeal to the producer’s need for reliability and cost-effectiveness.

-

Thermal Stability: Crucial for preventing degradation during the high-heat extrusion process, leading to consistent quality and fewer production line breaks.

-

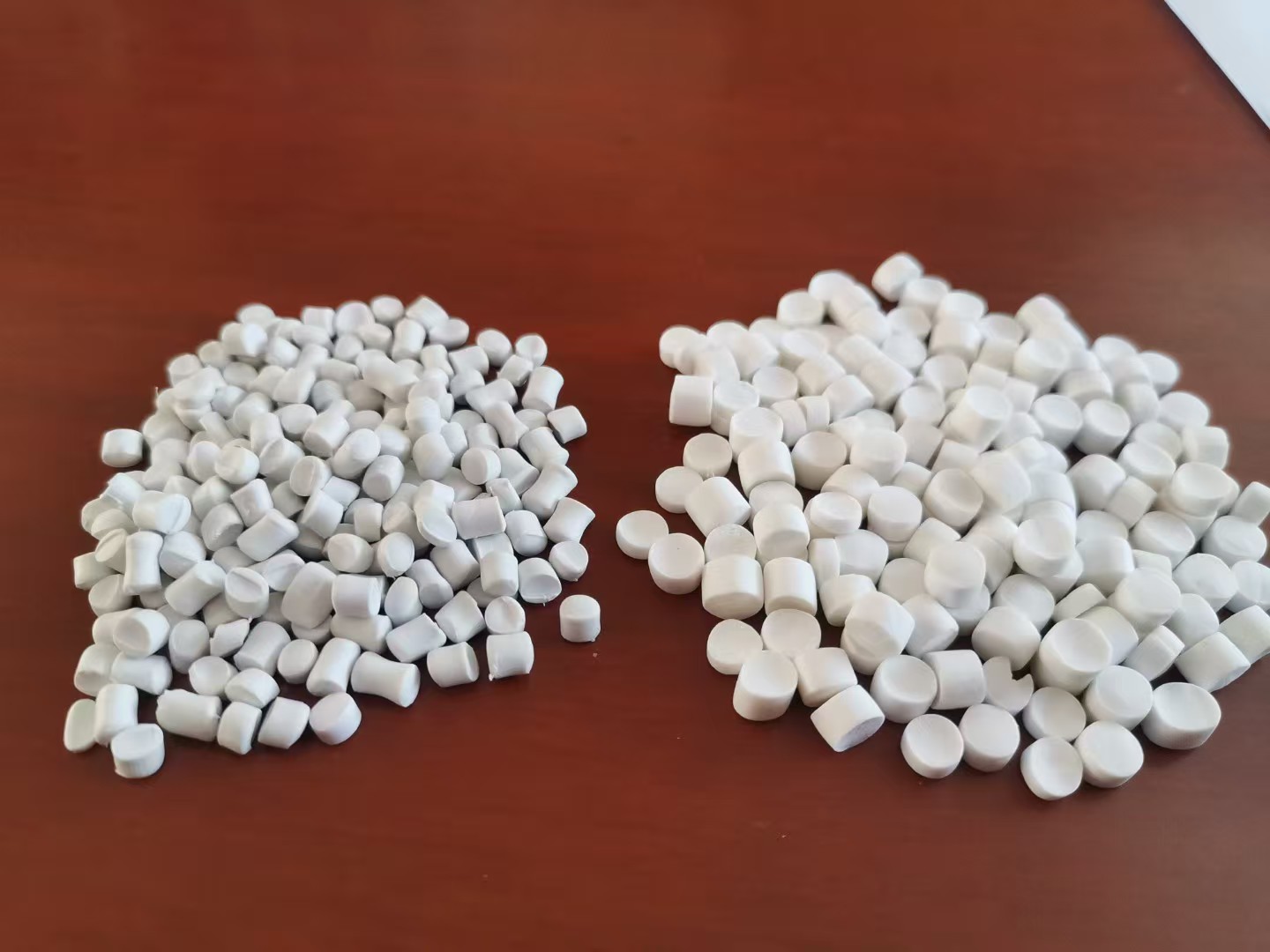

Excellent Processability: Your granules ensure smooth extrusion, easy casting into film, and minimal gel formation, resulting in high yields and manufacturing efficiency.