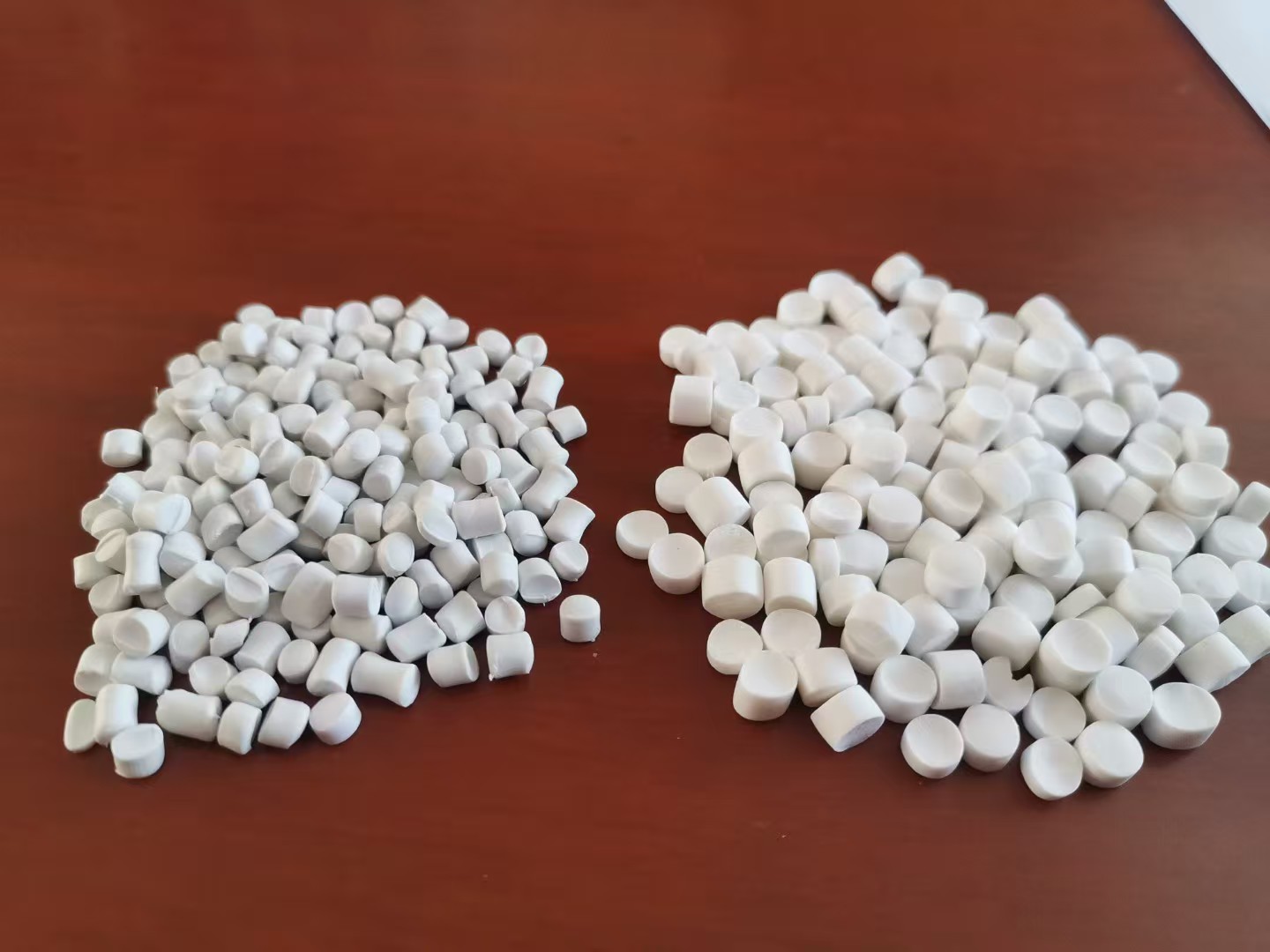

For sealing strips used in doors and windows, PVC granules are engineered into soft, flexible, and durable compounds that create effective, long-lasting seals against weather, noise, and temperature.

Product Introduction

PVC is the dominant material for door and window seals due to its excellent balance of properties. The granules are formulated into flexible PVC (PVC-P) compounds that are extruded into various profiles (like tubular gaskets, U-channels, or bulb seals). These seals are critical for improving energy efficiency, acoustic insulation, and weatherproofing in buildings.

Key Performance Requirements

For a sealing strip to perform reliably for years, the PVC granules must deliver on these core characteristics:

| Performance Area | Key Requirements | Why It Matters |

|---|---|---|

| Elasticity & Seal | High flexibility, excellent compression set resistance, good elastic recovery. | Ensures the strip compresses to fill gaps and springs back to maintain a tight seal over thousands of open/close cycles without taking a permanent set. |

| Weather Resistance | Excellent UV, ozone, and temperature resistance (-30°C to +70°C). | Prevents the seal from hardening, cracking, or degrading when exposed to sunlight, ozone, and extreme seasonal temperatures. |

| Durability | Good tensile strength, tear resistance, and abrasion resistance. | Withstands mechanical friction during window/door operation and physical contact without tearing or wearing out prematurely. |

| Aging & Appearance | Resistance to color fading, mildew, and surface chalkiness. | Maintains aesthetic appearance and functional integrity over the long term without unsightly discoloration or mold growth. |

Formulation & Processing

Achieving these properties requires a specialized flexible PVC formulation and precise processing:

-

Base Formulation: It starts with S-PVC (Suspension PVC) resin. A significant amount of plasticizers (like DINP, DOTP, or ESBO) is added to achieve the required softness and low-temperature flexibility.

-

Critical Additives: The mix includes heat stabilizers (e.g., Calcium-Zinc), fillers, pigments, and often UV absorbers and anti-fogging agents to meet the performance targets.

-

Production Process: The granules are typically processed via extrusion. The compound must have stable melt flow properties to produce seals with smooth surfaces, consistent dimensions, and no defects.

Applications

These PVC granules are used to manufacture sealing strips for:

-

Windows & Doors: Primary seals for casement, sliding, and tilt-and-turn windows; door bottom sweeps and perimeter seals.

-

Building Profiles: Seals for curtain walls, glass partitions, and prefabricated structures.

-

Transportation: Seals for automotive doors, trunks, and RV/container doors.

Conclusion

In short, PVC granules for sealing strips are not a generic product but a highly customized material engineered for resilience. By offering compounds that excel in weather resistance, elasticity, and long-term durability, you provide manufacturers with the essential material for creating high-performance, energy-saving building components.

If you have a specific hardness (Shore A) range or a particular color requirement in mind, I can help you explore the formulation adjustments needed.