If you’ve ever visited a large industrial facility that was bustling, sprayed chemical solvents, or had a busy port, you’ve observed them: long, winding conveyor belts, the arteries of modern industry, that are tirelessly responsible for transferring substances from one location to another. But have you ever considered what causes these essential arteries to flow without problems? The answer is located in a component that is frequently disregarded, but that is crucial: the conveyor roller.

Over time, the default option for this component has been the heavy, clunky, and rust-devouring steel roller. It was powerful, it was accessible, and it performed the task, or so we hoped. However, in today’s complex industrial environments, simply doing the job is no longer sufficient. Operators want greater efficiency, longer equipment life, safer workplaces, and lower costs of operation.

This is the location of the modern, cutting-edge solution: the PVC conveyor roller.

You may recognize “PVC” and think of simple plastic tubing, but the material used in a high-end performance PVC conveyor is completely different than that. It’s a complex, custom-made thermoplastic that is intended to excel over steel in every significant way.

Defining the PVC Conveyor Roller – More Than Just Plastic

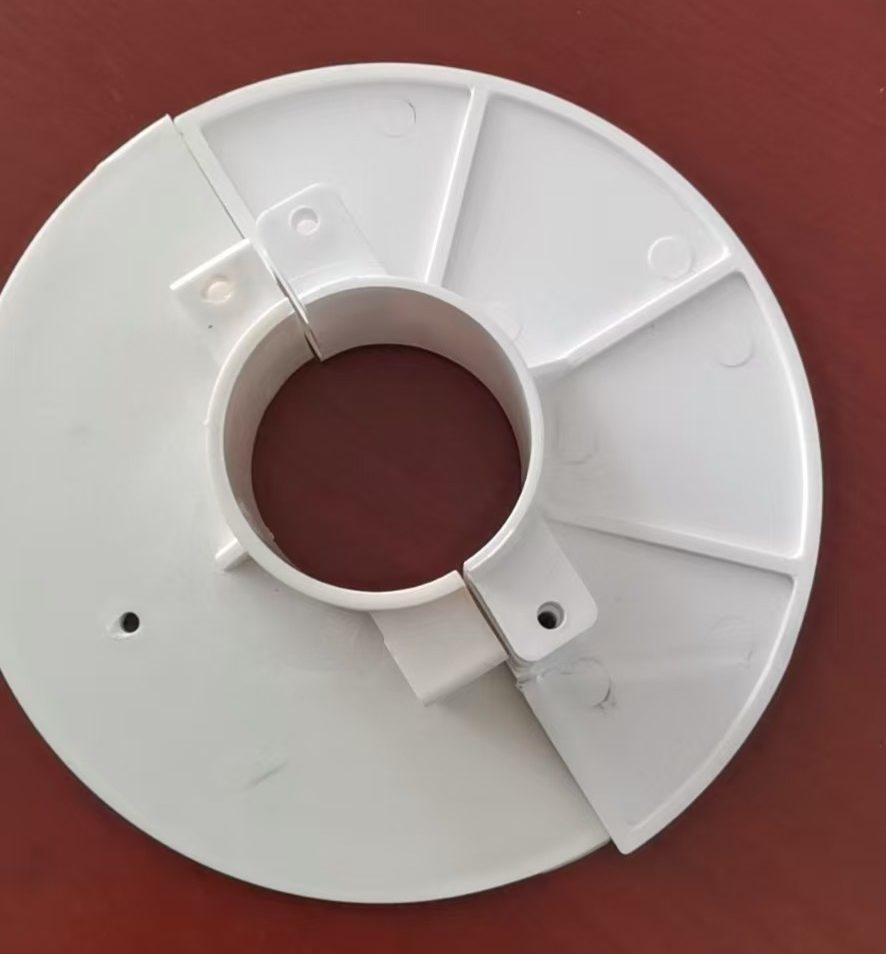

At its simplest, a PVC conveyor roller is a type of idler used in a belt conveyor system, designed to support the belt and the material it carries. But that simple definition hides a wealth of engineering. A high-quality PVC conveyor roller isn’t a single piece of plastic; it’s a precisely assembled system.

Let’s break down its three main components:

- The PVC Roller Shell: This is the main body and the star of the show. It’s not just any PVC. It is a specially modified, high-strength thermoplastic shell. In advanced models, like our Dual-Resistant rollers, the shell is infused with specialized additives during the manufacturing process. This gives the PVC conveyor roller its core properties, such as being flame-retardant and anti-static—features we’ll discuss in detail later.

- The Central Shaft: Running through the center of the shell is a high-strength steel shaft. This provides the structural rigidity and serves as the axle around which the roller rotates.

- The Bearing Assemblies: Housed at each end of the roller shell are precision bearing assemblies. These are the critical components that ensure the PVC conveyor roller rotates smoothly, with minimal resistance. They are protected by a sophisticated sealing system to keep contaminants out and lubrication in.

When these three parts are expertly combined, they create a component that is lightweight, durable, and packed with performance benefits that traditional steel rollers simply cannot match. A well-made PVC conveyor roller is a testament to modern material science and engineering.

The Core Features – What Makes a PVC Conveyor Roller Superior?

The real magic of a PVC conveyor roller lies in its unique performance characteristics. These aren’t just marginal improvements; they are fundamental advantages that solve the biggest pain points associated with traditional steel rollers.

1. Excellent Dual-Resistant Safety Properties

In many industries, safety is not just a priority; it’s a legal requirement. This is particularly true in environments like underground coal mines or chemical plants, where a single spark could lead to a catastrophic event.

- Anti-Static: A standard conveyor belt running over rollers can build up a significant static electric charge. A PVC conveyor roller with anti-static properties safely dissipates this charge, preventing the risk of a static discharge spark.

- Flame-Retardant: Through the addition of specialized flame retardants, the roller shell will not propagate a flame. If exposed to a source of fire, it will self-extinguish.

This “dual-resistant” capability makes this type of PVC conveyor roller an essential safety component, not just an operational one. Furthermore, its ability to operate stably in extreme temperatures, from a frigid -40°C to a hot 80°C, ensures reliable performance year-round.

2. High Wear Resistance & Belt Protection

This is perhaps the biggest economic advantage. A conveyor belt is one of the most expensive consumable parts of a conveyor system. A worn, rusted, or seized steel roller acts like a knife, gouging and tearing at the belt’s surface, dramatically shortening its life.

The PVC conveyor roller is designed to be the belt’s best friend.

- Low Wear Coefficient: It is manufactured from a modified, slick material with a very low coefficient of friction. The belt glides over it smoothly, significantly reducing wear and tear.

- No Material Adhesion: Unlike steel, which can rust and create a rough surface for wet materials like coal slurry or mud to stick to, the PVC surface is non-stick. This prevents material buildup on the roller, which is a primary cause of belt mistracking and damage.

The result? By switching to a high-quality PVC conveyor roller, facilities can extend their belt service life by 1 to 2 times. This alone can translate into enormous cost savings.

3. Superior Corrosion Resistance

Corrosion is the arch-nemesis of any steel component, especially in harsh environments. Rust not only weakens the roller but also increases friction, leading to higher energy consumption and eventual seizure.

A PVC conveyor roller is inherently immune to this problem.

- Chemically Inert: PVC is a polymer that does not react with water, acids, or alkalis. Its corrosion resistance is over 10 times greater than that of steel rollers.

- Ideal for Harsh Environments: This makes the PVC conveyor roller the perfect choice for damp, watery, dusty, and muddy environments. It thrives in conditions that would destroy a steel roller in a matter of months, such as in chemical processing plants, docks, ports, and mining operations.

4. Effective, Multi-Stage Sealing

What is the number one killer of any roller, steel, or polycarbonate? Bearing failure. What is the number one cause of bearing failure? Contamination. Dust, water, and grit enter the bearing assembly and destroy the lubrication; the assembly will stop grinding.

A premium version of the PVC conveyor roller is equipped with a security system similar to the fortress. This is typically a multi-step, labyrinth-style seal that creates a long, difficult path for parasites to follow. It possesses waterproof, dustproof, and anti-gas corrosion properties. This effective defense increases the life of the internal bearings by years, not by months.

5. Lightweight and Easy to Handle

Anyone who has had to replace a heavy steel conveyor roller, often in a cramped, awkward space high up on a conveyor structure, knows how difficult and dangerous it can be.

A PVC conveyor roller offers a simple but profound benefit: it’s light. It weighs approximately 1/3 less than an equivalent metal roller. This has several important implications:

- Easier & Safer Installation: Technicians can handle and install the rollers more easily, reducing worker fatigue and the risk of strains or injuries.

- Reduced Structural Load: On very long conveyor systems, the cumulative weight reduction can lessen the overall load on the support structure.

6. Noise Reduction & Eco-Friendly Operation

The pollution of industrial sounds is becoming a concern for the health of workers and environmental regulations. The constant grinding of a conveyor belt, especially the fasteners, which hit hard steel rollers, can lead to a deafening work environment.

The thermoplastic material of a PVC conveyor roller is naturally dampened by vibrations. It attenuates the impact and sound, similar to the difference between dropping a stone on concrete or a rubber mat. This decreases the noise associated with the belt and the roller, which contributes to a more environmentally friendly and lessening workplace.

Applications – Where Does the PVC Conveyor Roller Shine?

Thanks to its unique combination of safety, durability, and performance, the PVC conveyor roller is not a niche product. It is a versatile solution that provides immense value across a wide range of demanding industries.

- Mining: This is a primary application. The dual-resistant (anti-static and flame-retardant) properties are often mandatory for underground coal mining. The superior corrosion and wear resistance make it perfect for handling abrasive ores and slurries in wet, dusty conditions.

- Chemical Processing: In plants where corrosive chemicals or vapors are present, the chemical inertness of a PVC conveyor roller ensures a long and reliable service life where steel would quickly fail.

- Docks & Ports: The constant exposure to saltwater spray and high humidity makes ports one of the most corrosive environments imaginable. The PVC conveyor roller thrives here, resisting rust and ensuring smooth operation for ship loaders and unloaders.

- Food Processing: In applications where hygiene is key, PVC rollers are easy to clean and do not rust, preventing contamination of the product.

- General Industry: From cement plants to fertilizer factories, any application involving dust, moisture, and a need for high reliability is a perfect fit for a high-performance PVC conveyor roller.

The Hallmarks of Quality – What to Look for in a Supplier

Not all plastic rollers are created equal. As a buyer, it’s crucial to know how to distinguish a high-performance PVC conveyor roller from a cheap imitation.

Look for a supplier who emphasizes the following:

- Premium Material & High Strength: The manufacturer should use high-quality, modified raw materials, not just standard PVC, to ensure superior strength and impact resistance.

- Stable Performance & High Precision: The roller should exhibit minimal runout (wobble), which reduces vibration and belt wear. This is a sign of high-precision manufacturing.

- Durable & Wear-Resistant Construction: The product should be backed by data or case studies demonstrating its excellent wear resistance and long service life.

- Reliable & User-Friendly Design: A well-designed PVC conveyor roller is easy to install and performs reliably without frequent attention.

- Customizable Solutions: Every conveyor system is slightly different. A top-tier manufacturer will act as a partner, offering customization options to meet your specific needs (e.g., non-standard lengths, different shaft ends). As a direct manufacturer, this ability to provide tailored solutions is a key advantage.

The Smart, Modern Choice for Your Conveyor System

The question is no longer “Why should I switch from steel?” The real question is “Why wouldn’t I?”

The PVC conveyor roller is a clear example of how modern material science can solve long-standing industrial problems. It offers a powerful combination of enhanced safety, superior durability, and lower total cost of ownership that traditional steel rollers simply cannot compete with.

By choosing a high-quality PVC conveyor roller, you are not just replacing a part. You are making a strategic upgrade to your entire conveyor system. You are choosing to:

- Protect your most expensive asset (the conveyor belt).

- Enhance the safety of your workplace.

- Reduce your long-term maintenance costs and labor.

- Improve your operational efficiency and uptime.

It’s a smarter, safer, and more cost-effective solution for any modern industrial operation. The next time you look at your conveyor system, don’t just see rollers—see an opportunity for a significant and lasting improvement.