For PVC granules used in mine electric cable hooks, the specifications are defined by mandatory safety standards for coal mining environments. The material must be both flame-retardant and anti-static to prevent fires and explosions.

Here are the main specifications and formulation components for this application:

Key Specifications for High-Strength Mine Cable Hooks

| Property | Target Specification | Importance for Heavy Loading & Safety |

|---|---|---|

| Mechanical Strength | ||

| • Tensile Strength | ≥ 40 – 50 MPa | Primary indicator of the material’s ability to withstand pulling forces without breaking. |

| • Impact Strength (Izod Notched) | ≥ 15 kJ/m² | Crucial for toughness, preventing brittle fracture from sudden shocks or impacts. |

| • Flexural Modulus | ≥ 2,500 MPa | Indicates stiffness; a high modulus ensures the hook does not bend or deform significantly under load. |

| • Bearing Capacity | Designed to meet ≥ 160 kg – 2000 kg (product-dependent) | The ultimate functional requirement, validated through product testing. |

| Safety (Non-Negotiable) | ||

| • Flame Retardancy | UL94 V-0 (or equivalent mining standard like GB/T 16412) | Prevents flame propagation in case of fire. |

| • Anti-Static Property | Surface resistivity ≤ 3×10⁸ Ω (often targeting 10⁶ – 10⁹ Ω) | Prevents static discharge that could ignite flammable gases. |

| Durability | ||

| • Heat Deflection Temp (HDT) | ≥ 70°C @ 1.8 MPa | Ensures shape is maintained under load in warm mine environments. |

| • Density | ~1.35 – 1.50 g/cm³ | Higher filler/modifier content increases density but also strength. |

Formulation Guidance

Achieving these specs requires careful formulation. Here are typical additives used in patented formulas for mining applications:

-

Base Resin: PVC Resin (SG-2 to SG-5 type) is common, with SG-5 being frequently used.

-

Anti-static Agents: Highly Conductive Carbon Black (10-40 parts) is a primary agent. Graphene or Quaternary Ammonium Salts are also used in newer formulas.

-

Flame Retardants: Antimony Trioxide (Sb₂O₃) is a classic choice, often used with Chlorinated Paraffins. Modern formulas also use Aluminum Hypophosphite, Brominated Paraffin, or Melamine Salts.

-

Plasticizers: For flexibility, use TOTM, DIDP, or DOP (30-80 parts).

-

Other Key Additives: Calcium-Zinc Stabilizers (for heat stability), Impact Modifiers (e.g., CPE, MBS for toughness), and Lubricants (e.g., paraffin).

Production & Market Advice

-

Processing: The compound is mixed in a high-speed mixer and then melt-extruded and granulated, with temperatures typically controlled between 130-170°C.

-

Compliance & Certification: For the Chinese market, obtaining the Coal Mine Safety Certification (“煤安证”) is typically mandatory for products used in coal mines. Adhering to relevant industry standards for cable materials is also crucial.

-

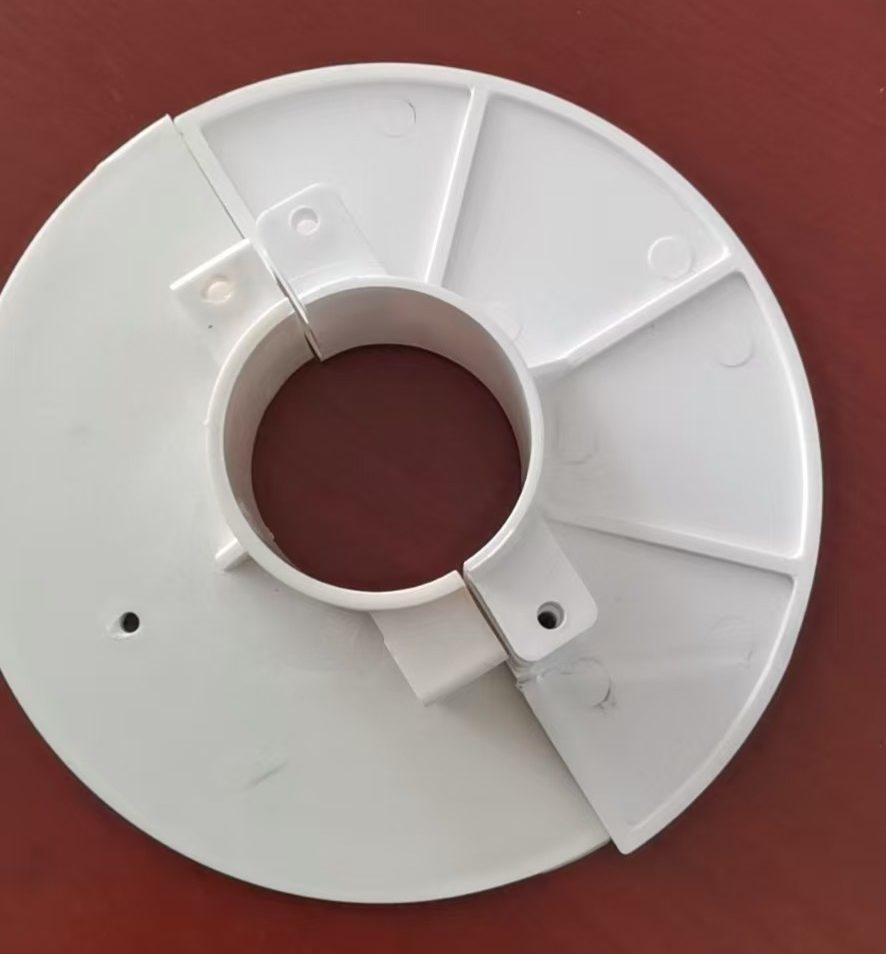

Product Naming: Following established market conventions can be helpful. Products are often named with patterns like “GL-PVC-[Diameter]” (e.g., GL-PVC-38, GL-PVC-50).