Precision Engineering: Specialized PVC Granules for High-Performance Wire Conduits

In modern electrical infrastructure, building construction, and industrial systems, wire conduits are the unsung heroes that ensure the safe and reliable transmission of power and data. They are far more than simple pipes; they form a critical protective system that provides mechanical safeguarding, environmental isolation, and long-term routing guidance. Consequently, the raw material—PVC granules—must meet a stringent and comprehensive set of performance criteria. PVC granules engineered specifically for wire conduits must achieve a perfect balance, through precise formulation, between rigidity, toughness, weatherability, and safety.

The Core Demands of Wire Conduits and Corresponding Material Requirements

-

Superior Mechanical Protection:

-

Conduit Requirement: Conduits must withstand impact during installation, crushing, foot traffic, and long-term soil pressure to prevent deformation or rupture that could damage the internal cables.

-

Material Solution: This demands PVC granules with high Ring Stiffness (resistance to external pressure), exceptional Impact Strength, and excellent Creep Resistance. The material must maintain its shape under load and resist brittle fracture.

-

-

Robust Environmental Resistance:

-

Conduit Requirement: Whether buried underground, exposed outdoors, or used in chemical plants, conduits must resist moisture, chemical corrosion, UV degradation, and extreme temperatures.

-

Material Solution: The PVC formulation must possess outstanding Chemical Resistance, low Water Absorption, high UV Stability, and reliable performance across a wide temperature range (typically from -20°C to 60°C or beyond).

-

-

Inherent Safety and Longevity:

-

Conduit Requirement: In the event of an electrical fault, conduits should inhibit flame spread and maintain strong insulating properties. Their physical integrity must remain stable for decades.

-

Material Solution: The material needs to achieve high Flame Retardancy ratings (e.g., UL 94 V-0 or compliance with GB/T 2408 standards) and offer stable dielectric properties. Long-term Thermal Stability and Anti-Aging capabilities are fundamental for ensuring service life.

-

The Specialized PVC Granule Formulation to Achieve These Features

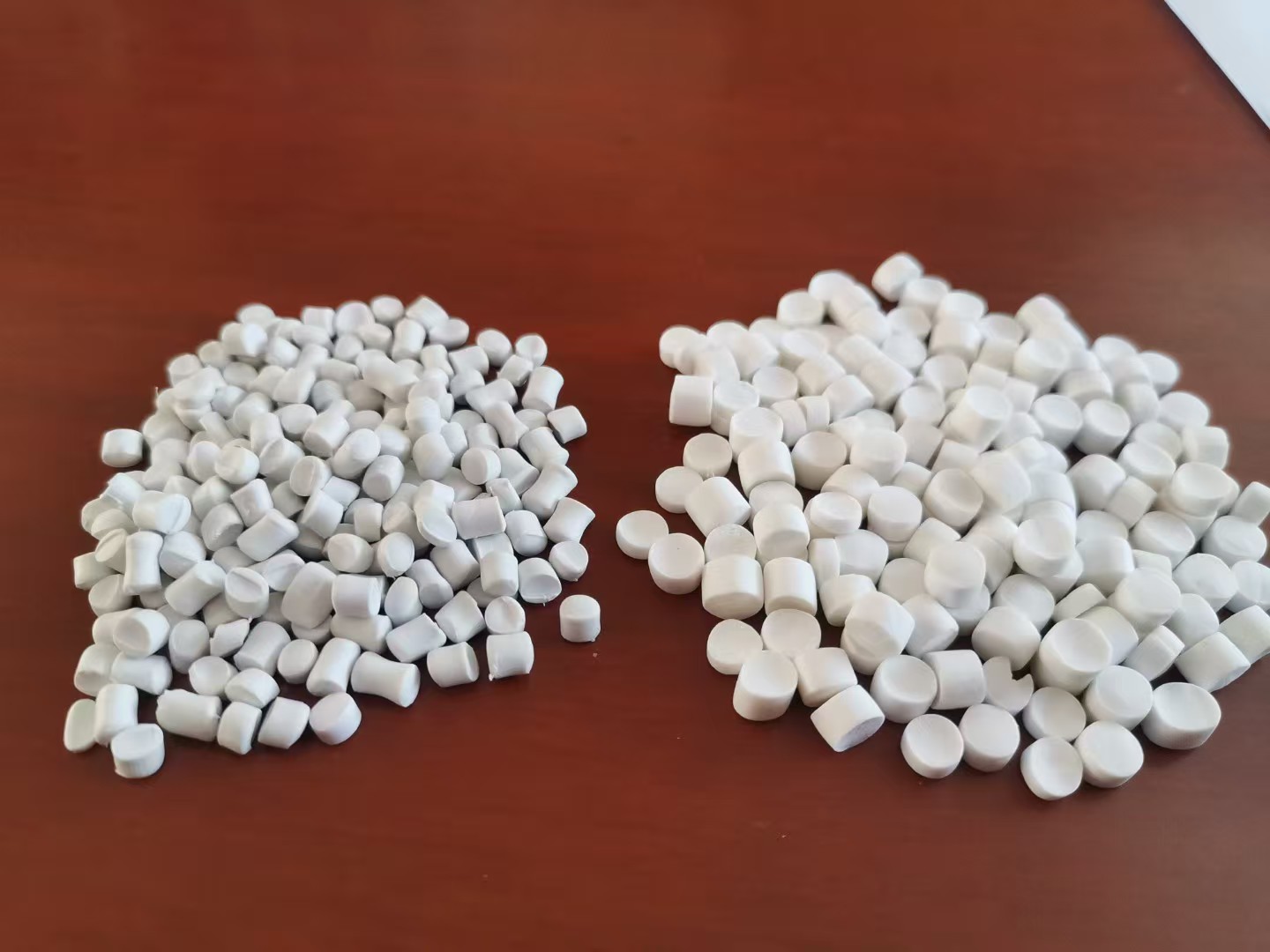

Meeting these combined demands requires a systematically engineered PVC compound, not a standard mix. Here is the formulation strategy:

-

Core Resin & Stabilization System:

-

A high molecular weight PVC resin (with a high K-value, e.g., K-66 or above) forms the base, providing superior ultimate physical strength.

-

An efficient and environmentally friendly Calcium-Zinc (Ca/Zn) composite heat stabilizer system is essential. This system prevents thermal degradation during high-temperature extrusion, ensures color stability, and provides long-term stability during the product’s service life, supporting its weatherability.

-

-

Toughening and Reinforcement System:

-

Adding Impact Modifiers (such as CPE or ACR) is crucial. These agents absorb and disperse impact energy, preventing the conduit from cracking under shock or at low temperatures.

-

Surface-treated, fine-ground Calcium Carbonate (CaCO₃) is used as a filler. Beyond cost optimization, it acts as a reinforcing agent when well-dispersed, significantly enhancing the material’s rigidity, dimensional stability, and heat resistance.

-

-

Functional Additive Package:

-

Flame Retardant System: Incorporating synergistic agents like Antimony Trioxide (Sb₂O₃) with chlorinated paraffins enables the material to self-extinguish quickly, meeting stringent fire safety standards.

-

Weathering System: UV absorbers and light stabilizers are integrated to absorb or quench ultraviolet radiation, dramatically slowing down yellowing, chalking, and strength loss caused by sunlight exposure.

-

Processing Lubrication System: A carefully balanced blend of internal and external lubricants (e.g., polyethylene wax, stearic acid) ensures uniform plastification, high melt strength, smooth extrusion surface finish, and precise dimensional control for efficient production.

-

In summary, a high-quality PVC granule for wire conduits is the physical embodiment of sophisticated chemical formulation. Through scientific component design and synergy, it transforms base PVC resin into a high-strength, high-toughness, flame-retardant, and weather-resistant engineering material. Selecting such a specialized compound means choosing durable, stable, and safe protection for cable systems—a core requirement placed on foundational materials by modern infrastructure.