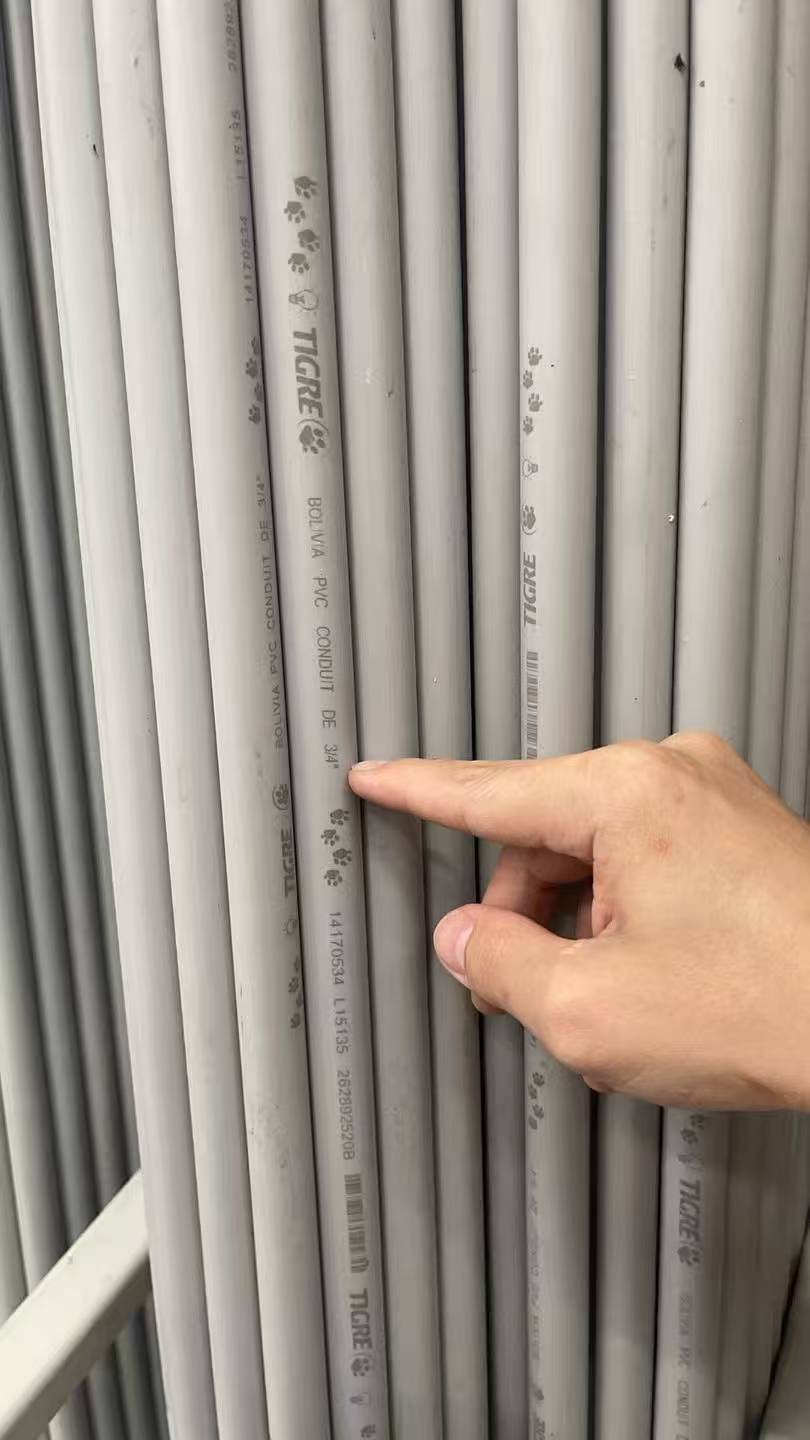

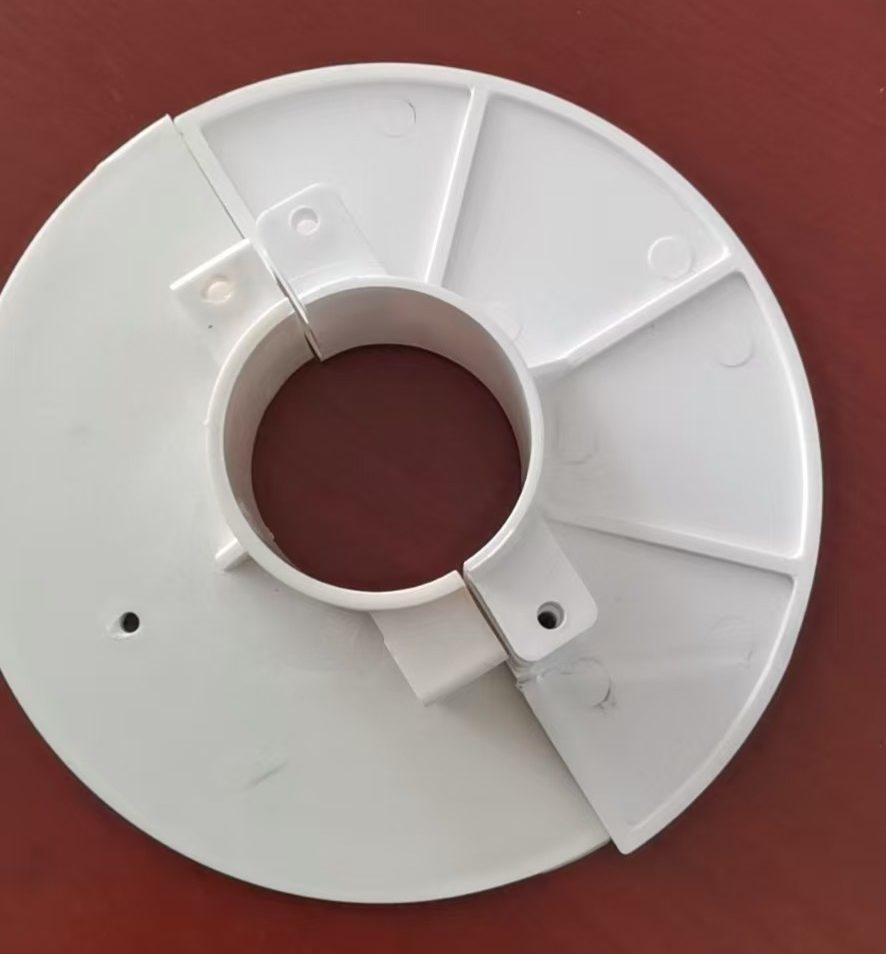

Premium PVC Injection Molding Granules for Construction Formwork: Reserved Hole Suspension Molds & Embedded Sleeves

Shandong Dingshengtong (DST PVC) provides specialized PVC injection molding compounds engineered for precision construction accessories, specifically Pipeline Reserved Hole Suspension Molds and Embedded Sleeves. These components are critical for creating clean, accurate openings for pipes and conduits in concrete walls and floors. Our granules are formulated to produce molds and sleeves that offer unparalleled efficiency, durability, and reliability on the job site, replacing traditional wood, steel, or inferior plastic methods.

Why Choose Our PVC Granules for Formwork Applications?

Choosing the right material for formwork directly impacts project efficiency, cost, and finish quality. Our PVC granules are engineered to address the specific pain points of concrete forming, offering a modern, superior alternative.

1. Unmatched Precision and Superior Concrete Finish

Our compounds are designed for high-precision injection molding, ensuring every suspension mold and embedded sleeve has consistent dimensions, sharp edges, and smooth surfaces. This precision translates directly to the construction site: it creates perfectly formed, clean-edged openings in cured concrete. The smooth, low-surface-energy finish of our PVC significantly reduces concrete adhesion, allowing for easy, clean demolding. This eliminates the risk of damaging the concrete edges during removal—a common issue with rough wood or rusty steel forms—and minimizes post-processing labor for a professional finish every time.

2. Engineered for Job-Site Durability and Reusability

Construction environments demand toughness. Our PVC formulation delivers high rigidity and excellent impact resistance (with a target Notched Izod Impact Strength of ≥ 8 kJ/m²), allowing these components to withstand the pressures of wet concrete, accidental drops, and rough handling without cracking or deforming. Unlike single-use cardboard or foam forms, or corrosive metal ones, products made from our granules are built for multiple reuses. This reusability across numerous pours and projects offers tremendous cost savings, reduces waste, and provides a reliable return on investment. The material is inherently resistant to moisture, rust, and the alkaline chemicals present in concrete, ensuring long-term storage and performance without degradation.

3. Lightweight Efficiency and Enhanced Safety

Weighing approximately one-third of equivalent steel components, our PVC-based molds and sleeves dramatically improve on-site logistics. Their lightweight nature makes them easier and safer for workers to transport, position, and install, reducing physical strain and speeding up the formwork process. The efficiency gains are substantial: faster setup and teardown times contribute to shorter project cycles. Furthermore, the material’s properties ensure reliable performance, reducing the risk of formwork failure and contributing to a safer, more predictable worksite.

Key Technical Specifications & Benefits

| Property | Target Specification | Practical Benefit on Site |

|---|---|---|

| Flexural Modulus | ≥ 2500 MPa | Provides the high rigidity needed to resist bending and deformation under the hydrostatic pressure of wet concrete. |

| Tensile Strength | ≥ 45 MPa | Ensures structural integrity, preventing cracks or breaks during handling, installation, and concrete pouring. |

| Impact Strength | ≥ 8 kJ/m² (Izod Notched) | Withstands accidental impacts from tools or handling without fracturing, ensuring a long service life. |

| Heat Deflection Temp. | ≥ 70°C @ 1.8 MPa | Maintains dimensional stability if exposed to warm weather or curing concrete heat. |

| Surface Finish | Smooth, Low Adhesion | Enables easy, clean demolding for perfect concrete edges and reduces cleaning time. |

Upgrade your construction formwork strategy with DST PVC’s high-performance granules. By combining precision, durability, and lightweight efficiency, our material empowers you to achieve higher quality results, reduce labor costs, and improve project timelines. Contact our technical team to discuss your specific mold designs and receive tailored compound recommendations.