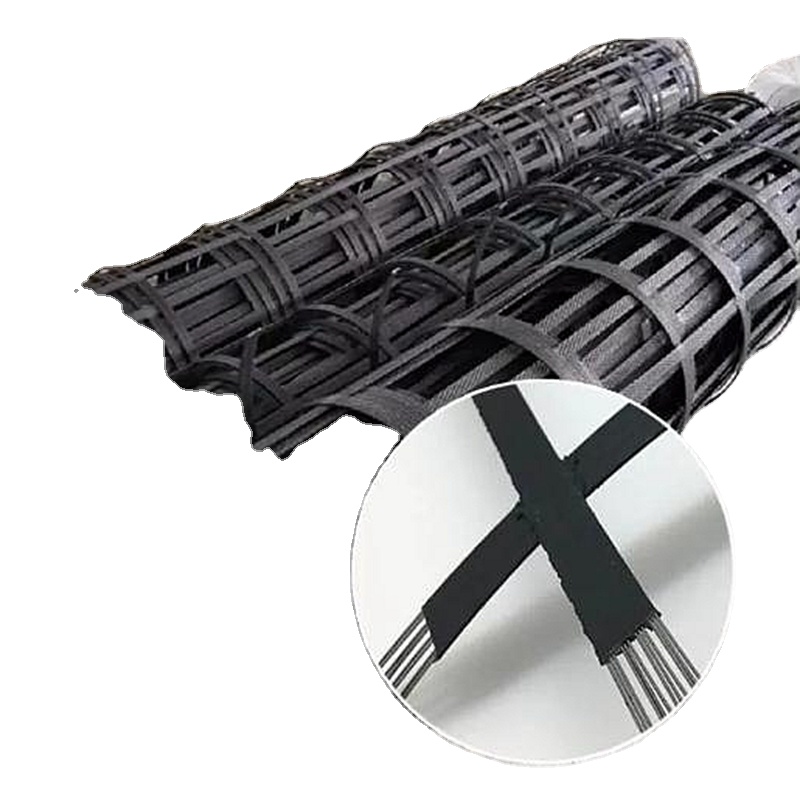

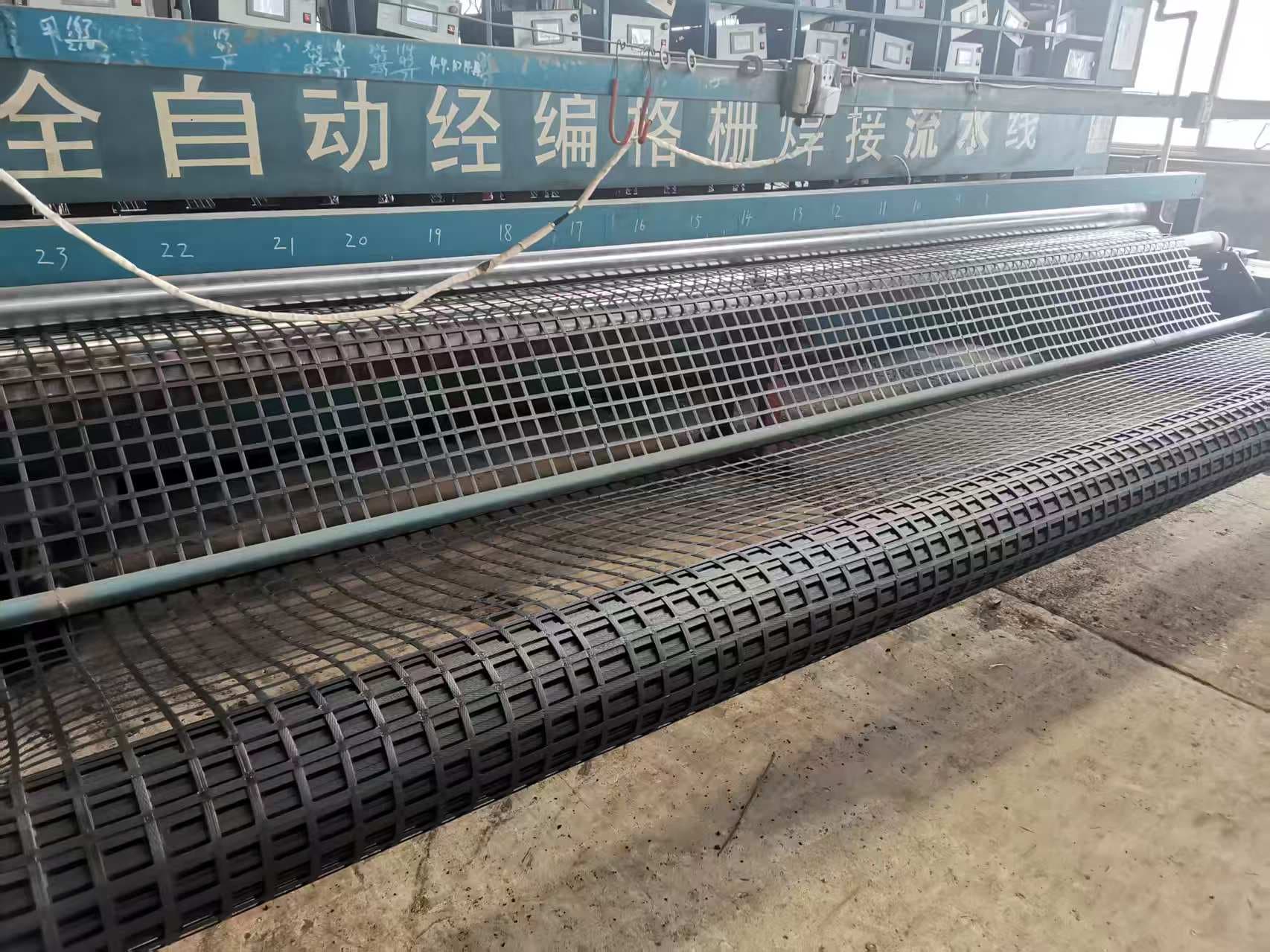

PVC Compound for Steel-Plastic Composite Mine Support Nets

Product Overview

Our specialized PVC compound is engineered for the critical application of steel-plastic composite support nets in mining operations. These composite nets, which integrate a high-strength steel mesh core with a durable PVC coating, represent a significant advancement in mine safety infrastructure. Our compound is formulated to create a protective, flexible, and resilient coating that significantly enhances the performance and longevity of traditional steel mesh in the demanding underground environment.

Core Function & Composite Advantage

The primary role of the PVC coating in this composite structure is to provide a durable protective barrier. It encapsulates the steel mesh, shielding it from the primary causes of degradation in mines:

-

Corrosion: Protects against moisture, acidic mine water, and alkaline substances.

-

Abrasion: Resists wear from rock contact and mechanical stress.

-

Impact: Adds a layer of resilience against rockfalls and dynamic loads.

This synergy creates a superior support net where the steel provides the core tensile strength for load-bearing, and the PVC coating ensures long-term durability, preventing rust-induced weakening and subsequent failure.

Key Performance Features of Our PVC Compound

-

Exceptional Corrosion & Chemical Resistance: Formulated to withstand prolonged exposure to damp, chemically aggressive mine atmospheres, drastically extending the service life of the support system compared to uncoated steel.

-

High Flame Retardancy & Anti-static Properties: Designed to meet stringent mine safety standards. The compound features excellent flame-retardant properties to inhibit fire spread and can be formulated with anti-static additives to reduce the risk of sparking.

-

Superior Mechanical Durability: Offers excellent abrasion resistance to withstand friction against rocks and machinery. It maintains high tensile strength and elongation at break, ensuring the coating remains intact and flexible under deformation without cracking or peeling from the steel substrate.

-

Strong Adhesion & Environmental Resistance: Engineered for excellent adhesion to galvanized or treated steel surfaces, preventing delamination. It also possesses good resistance to mold and mildew, which are common in humid mine environments.

Benefits for Mining Operations

-

Enhanced Safety & Longevity: Creates a more reliable and durable support system that maintains its integrity over time, reducing the frequency of replacements and associated underground maintenance risks.

-

Reduced Lifecycle Cost: The extended service life of the composite net, due to corrosion protection, translates into lower long-term material and labor costs.

-

Improved Handling & Installation: The PVC coating makes the nets easier and safer to handle than bare, sharp steel mesh, while remaining suitable for standard installation practices.