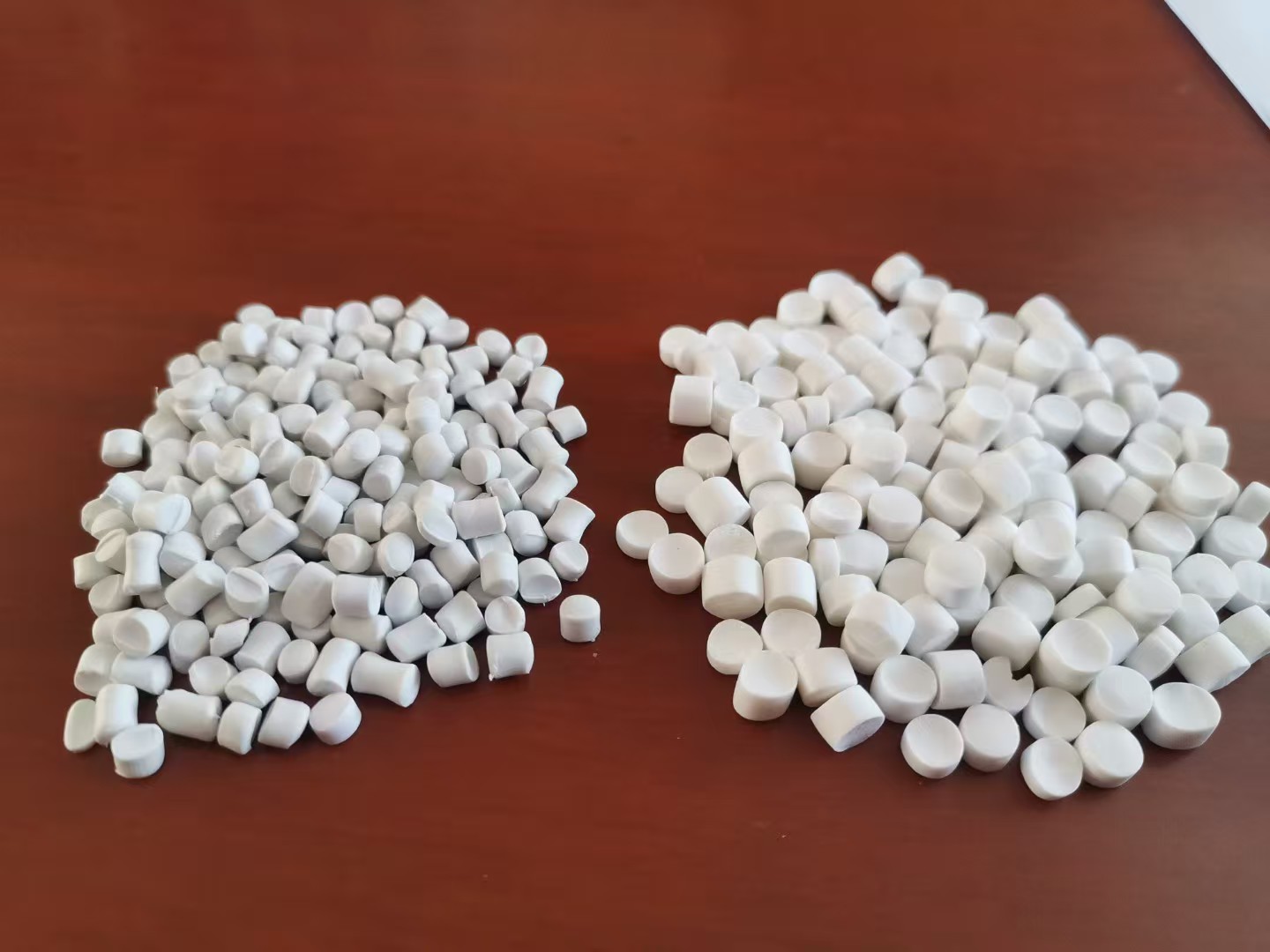

Electric Cable Manufacturing Process Using PVC Granules

The manufacturing of electric cables with PVC insulation or sheathing typically involves the following eight major steps:

1. Raw Material Preparation

PVC Granules Selection

Factories choose specific PVC compounds depending on cable type:

-

PVC insulation granules (for conductor insulation)

-

PVC sheathing granules (for outer jacket protection)

-

Specialized PVC compounds (e.g., flame-retardant, low-smoke, high-flexibility, anti-cold)

Before use, PVC granules are normally:

-

dried (to remove moisture)

-

pre-mixed with stabilizers or color masterbatch (if needed)

2. Copper/Aluminum Wire Drawing

Large copper or aluminum rods are drawn through a series of dies to reduce the diameter.

Process:

Rod → Annealing machine → Multi-die drawing → Fine wire → Take-up reel

The goal is to produce smooth, uniform strands suitable for conductor stranding.

3. Conductor Stranding

Multiple drawn wires are twisted together to form a conductor with:

-

higher flexibility

-

better electrical performance

Types of stranding:

-

Tight-stranded

-

Sector-shaped

-

Concentric

-

Compacted (for power cables)

4. PVC Granules Extrusion for Insulation

This is the critical stage where PVC granules are melted and applied onto the conductor.

Extrusion Steps:

-

PVC granules fed into the extruder hopper

-

Heated in barrel (160–190°C depending on formulation)

-

Melt passes through screw compression

-

Melted PVC is extruded around conductor

-

Cooled in water trough

-

Spark tester checks insulation purity

Result:

A perfectly round PVC-insulated conductor.

5. Twisting / Cabling (If Multi-core Cable)

For multi-core cables (2, 3, 4, or more insulated wires), the insulated conductors are twisted together.

May include:

-

fillers

-

binding tape

-

separator layers

This ensures cable roundness and mechanical stability.

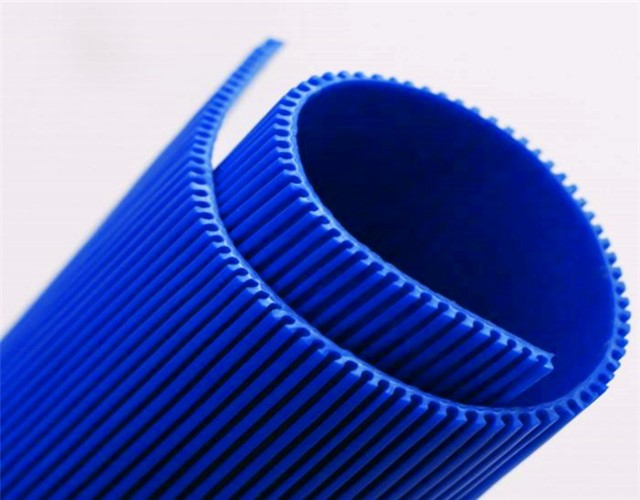

6. PVC Sheathing Extrusion (Outer Jacket)

A second extrusion process applies the outer PVC sheath.

PVC sheathing material must provide:

-

abrasion resistance

-

weather and UV resistance

-

flame retardancy

-

mechanical strength

Process is similar to insulation extrusion:

PVC granules → Extruder → Melt → Crosshead die → Cable sheathing → Cooling → Printing

7. Printing & Meter Marking

The finished cable is printed with:

-

cable type

-

size

-

voltage rating

-

length marking

-

manufacturing date / batch

Inkjet printers are used during line operation.

8. Winding, Packaging, and Quality Inspection

Final steps include:

-

winding onto coils or drums

-

visual inspection

-

electrical tests (resistance, dielectric strength, spark testing)

-

mechanical tests (tensile, elongation, ageing)

Once approved, cables are packaged and ready for shipment.