To achieve the standard performance for PVC-U DWV pipes, you need a carefully balanced formulation of additives. Each component plays a specific role in ensuring the final pipe meets the required mechanical strength, impact resistance, and processability.

Here is a breakdown of the necessary additive categories, their typical dosages, and their primary functions within the compound.

🧪 Essential Additives for PVC-U DWV Pipe Formulation

The core formulation is based on 100 parts by weight of PVC resin (phr). A typical “recipe” includes the following key additives:

| Additive Category | Specific Types & Examples | Typical Dosage (phr) | Primary Function |

|---|---|---|---|

| Heat Stabilizers | Calcium-Zinc (Ca/Zn), Organotin (e.g., Methyltin) | 2 – 4 | Prevents thermal degradation of PVC during high-temperature extrusion, maintaining material strength and color. |

| Impact Modifiers | Chlorinated Polyethylene (CPE), Acrylic-based modifiers (ACR) | 6 – 12 | Crucial for DWV. Absorbs energy to prevent brittle fracture, dramatically improving toughness and impact resistance. |

| Fillers | Precipitated Calcium Carbonate (CaCO₃), surface-treated for better bonding | 5 – 40+ | Increases stiffness (Ring Stiffness), reduces raw material cost, and improves dimensional stability. |

| Lubricants | Internal: Stearic Acid, Calcium Stearate External: Paraffin Wax, Oxidized Polyethylene Wax |

1 – 2 | Reduces friction: Internal (between PVC chains) aids fusion; External (between melt and equipment) ensures smooth processing and surface finish. |

| Processing Aids | Acrylic-based polymers (ACR processing aid) | 1 – 2 | Promotes uniform PVC particle fusion, improves melt strength for smooth extrusion, and helps prevent surface defects like “shark skin.” |

| Pigments | Titanium Dioxide (TiO₂) | 1 – 4 | Provides standard white or grey color and offers some protection against UV degradation for pipes exposed to light. |

💡 Key Formulation Insights for DWV Pipes

-

The Calcium-Zinc (Ca/Zn) Imperative: For modern, eco-friendly pipes (especially for potable water or wastewater), Calcium-Zinc stabilizers are the industry standard, having largely replaced lead-based stabilizers. They are essential for safe, compliant production.

-

Balancing Impact vs. Processability: The heart of a DWV formulation is the impact modifier (like CPE). However, its use increases melt viscosity. This is why a well-balanced lubricant system is non-negotiable—it counters the stickiness and ensures the tough compound can still be processed efficiently.

-

The Role of Fillers: Unlike pressure pipes, DWV pipes can utilize higher loadings of calcium carbonate because maximum hydrostatic pressure is less critical. This effectively boosts stiffness and reduces cost, but the filler must be of good quality and well-dispersed to avoid weakening the material.

-

What’s NOT in the Mix: Plasticizers (like DOP, DINP) are intentionally excluded. DWV pipes are made from rigid PVC-U (Unplasticized), so the formulation relies on impact modifiers for toughness, not plasticizers for flexibility.

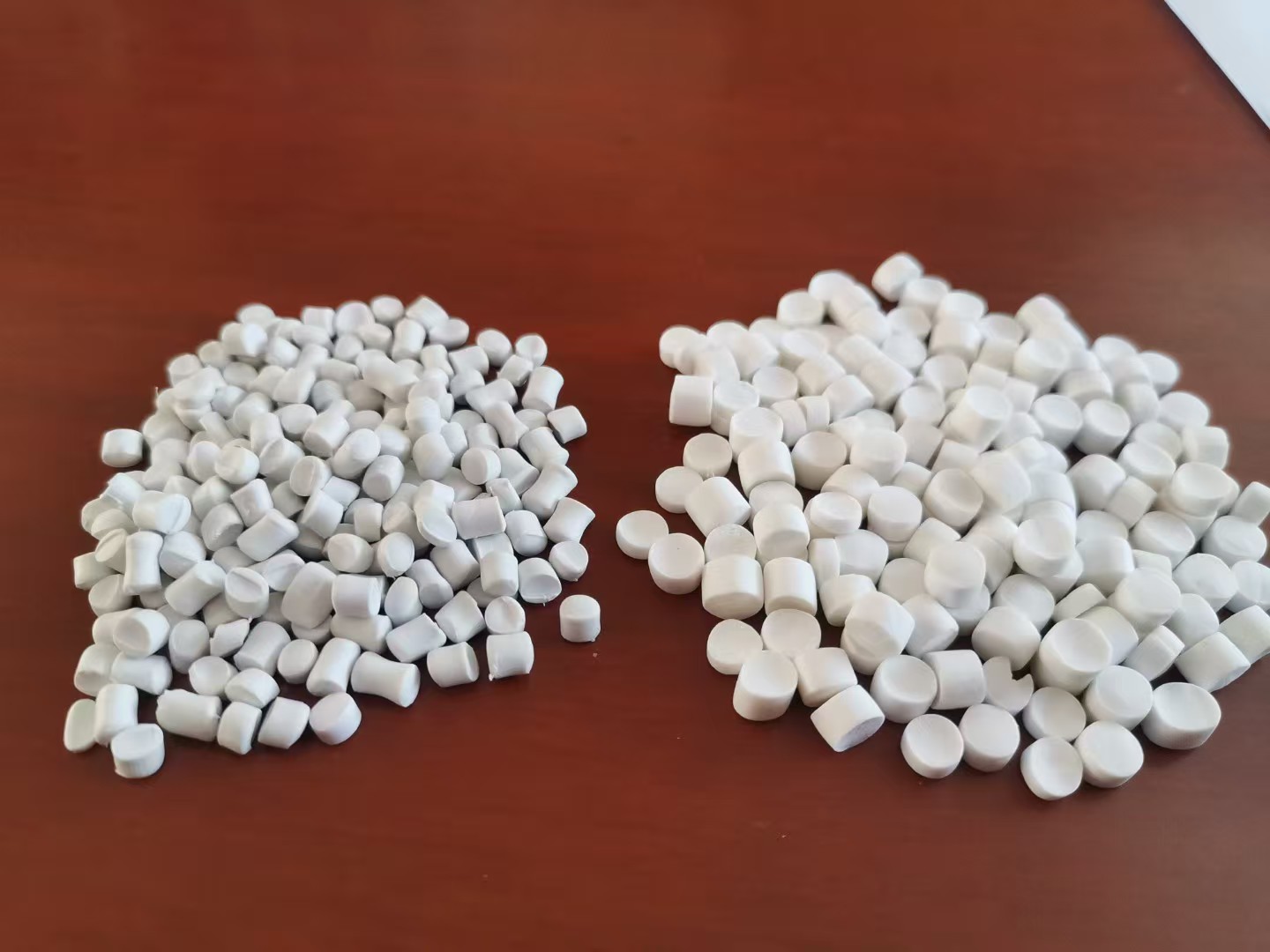

This additive system creates a synergistic effect, producing granules that extrude into pipes with the ideal balance of high impact strength, excellent ring stiffness, good thermal stability, and smooth processability.