Your Challenge, Our Formula: The Power of Customized PVC Granules

In today’s competitive market, off-the-shelf solutions often mean compromise. Your product—whether it’s a critical automotive component, a durable building material, or a consumer good—faces unique demands. Shouldn’t your raw material be designed to meet them?

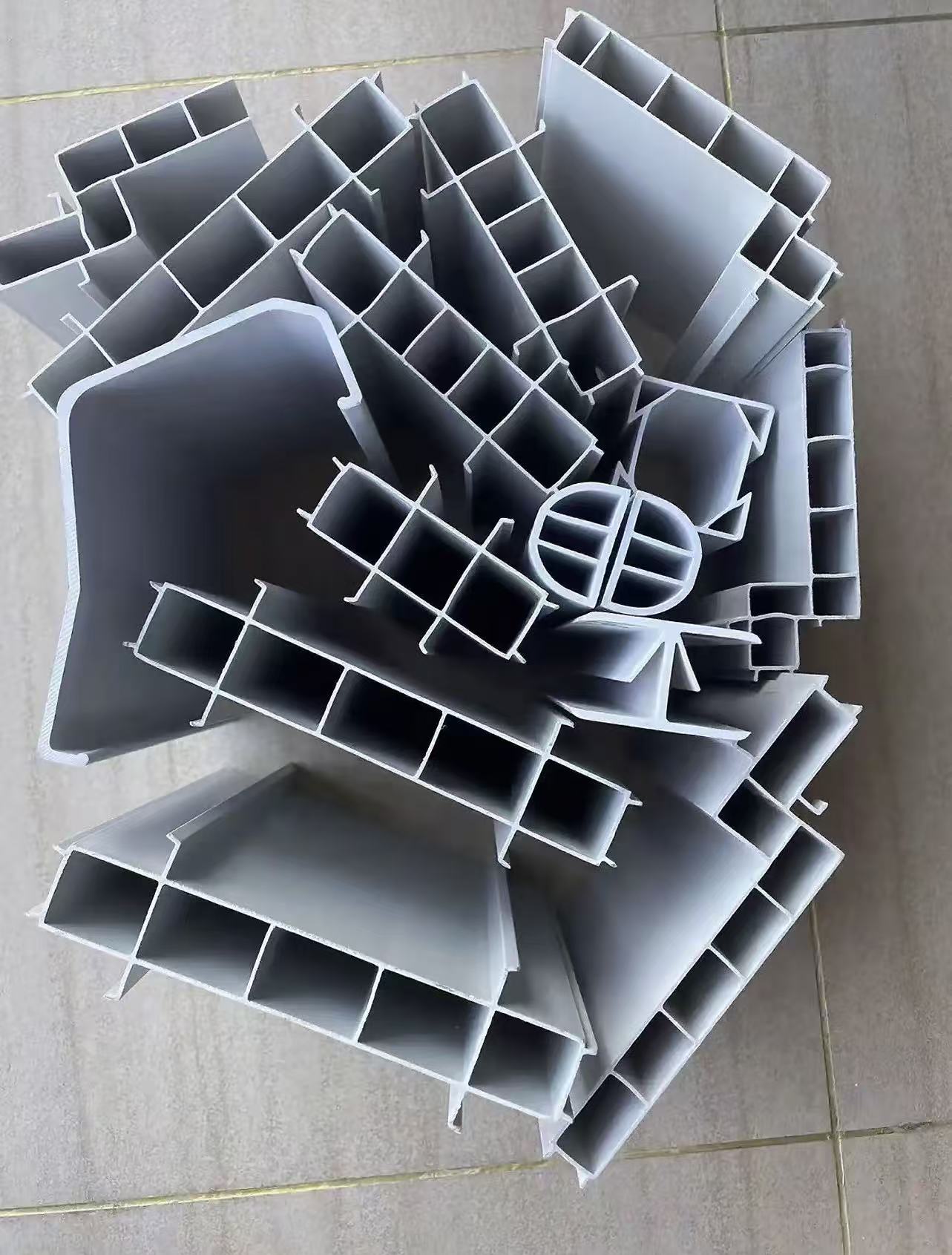

We move beyond standard grades to offer a true partnership: precision-engineered, customized PVC granules. We don’t just supply a product; we provide the exact material solution your application requires.

Why “Standard” Isn’t Always Good Enough

Every industry has its own set of challenges. A standard PVC compound might excel in one area but fall short in another. Consider:

-

A brake cable sheathing requires exceptional abrasion resistance and a low coefficient of friction.

-

A potable water pipe demands non-toxic, plasticizer-free formulation for absolute safety.

-

An outdoor wire duct needs high impact strength and superior UV stability to withstand the elements.

-

A food wrap must have crystal clarity and comply with stringent FDA regulations.

Generic granules force you to design around their limitations. Our customized approach eliminates this compromise.

Our Process: Collaboration from Concept to Production

Our service is built on a collaborative, methodical process to ensure your success.

1. Discovery & Challenge Definition:

It starts with a conversation. We dive deep into your application, performance requirements, processing methods (extrusion, injection molding), and the challenges you face.

2. Expert Formulation Design:

Our technical team designs a proprietary formulation. We adjust the levers of material science to create your perfect compound:

-

Base Polymer & Additives: Selecting the right PVC resin and integrating performance-enhancing additives like UV stabilizers, flame retardants, and anti-oxidants.

-

Mechanical Properties: Fine-tuning tensile strength, elongation, impact resistance, and hardness.

-

Special Characteristics: Engineering for properties like non-toxicity, eco-friendliness, plasticizer-free composition, or specific color requirements.

-

Processability: Optimizing for thermal stability and melt flow to ensure smooth, efficient production on your equipment.

3. Lab-Scale Production & Rigorous Testing:

We produce a sample batch in our lab and put it through a battery of tests to validate performance against your key specifications—from density and heat resistance to wear and low-temperature flexibility.

4. Sample Delivery & Industrial Scaling:

We provide samples for your evaluation. Once approved, we seamlessly scale up to industrial production, maintaining strict quality control for unwavering batch-to-batch consistency.

The Technical Levers We Control for You

| Your Requirement | Our Customization |

|---|---|

| Need higher impact strength? | We modify the impact modifier package. |

| Operating in extreme temperatures? | We optimize stabilizers and plasticizers for a wider service range. |

| Requiring a specific safety certification? | We formulate to meet UL, FDA, NSF, or RoHS standards from the start. |

| Want a unique color or opacity? | We develop a precise, consistent color masterbatch. |

| Facing production inefficiencies? | We enhance lubricity and thermal stability for faster, smoother processing. |

Proven Success Across Industries

-

Automotive: Developed a high-abrasion resistance, low-friction compound for brake cable sheathing, ensuring smooth operation and long life.

-

Construction: Engineered a rigid PVC-U with high Ring Stiffness and UV resistance for outdoor wire ducts that protect against environmental stress and physical impact.

-

Packaging: Created a crystal-clear, fully FDA-compliant non-toxic formulation for food-safe films and wraps.

-

Consumer Goods: Designed a soft, anti-slip, and easy-to-clean compound for stair mats, combining safety with durability.

Ready to Create the Perfect Material for Your Next Product?

Stop adapting your designs to the limitations of standard materials. Let us create the PVC granules that will make your product safer, more durable, and more competitive.

Contact us today for a free technical consultation. Together, we’ll define your needs, and we will provide a tailored formulation strategy and a custom sample for your evaluation.