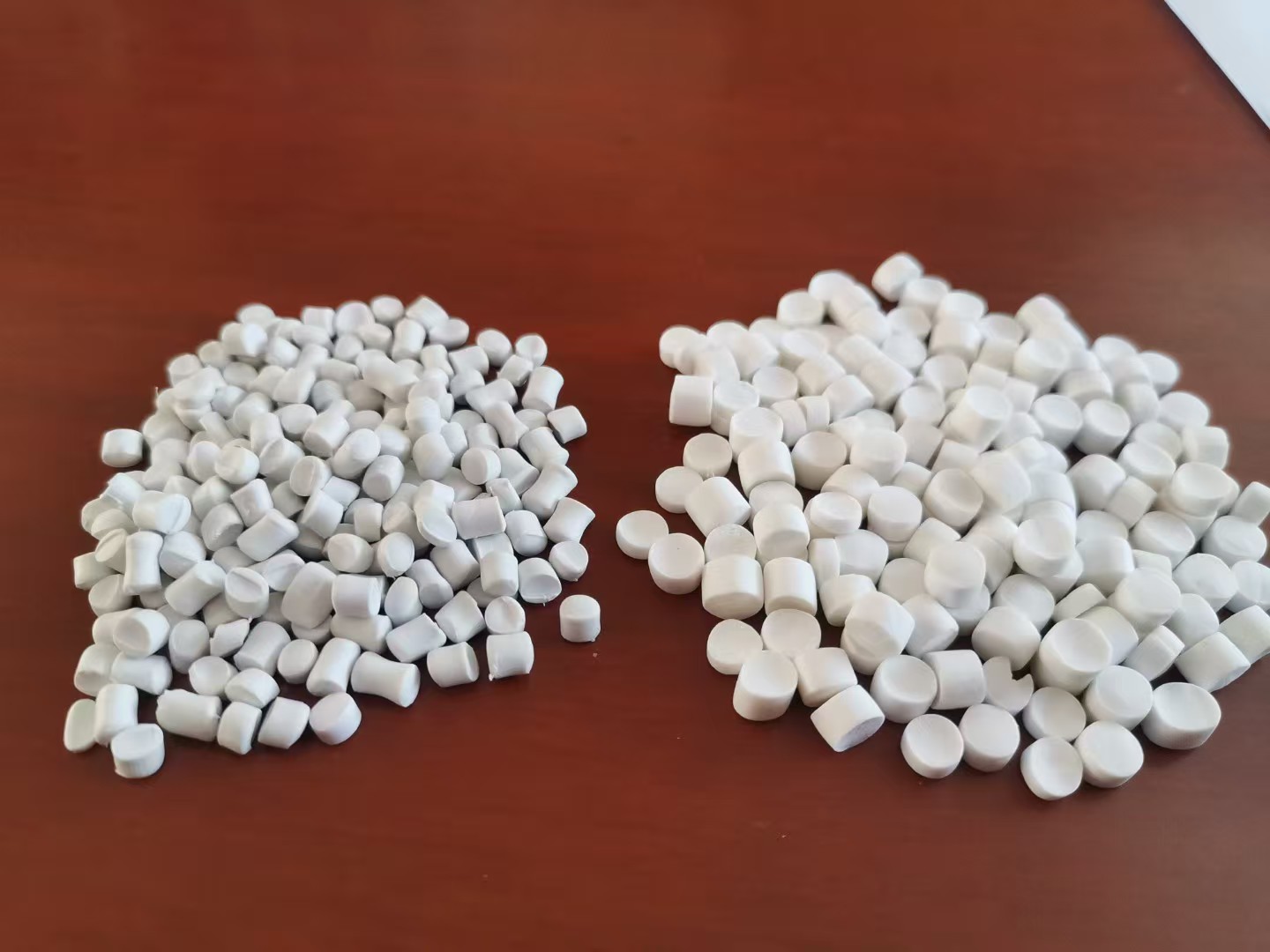

To choose the most suitable PVC granules for high-quality wire ducts, you should focus on specifications that ensure mechanical strength, heat resistance, and good processability. Key standards and product examples highlight critical performance metrics.

Here is a summary of the main specifications to guide your selection:

| Specification Category | Key Parameters to Focus On | Why It Matters for Wire Ducts |

|---|---|---|

| Material Type | PVC-U (Unplasticized) | Provides the rigidity and strength needed for protective ducting. |

| Mechanical Properties | Tensile Strength, Impact Resistance, Ring Stiffness | Ensures the duct can withstand crushing forces, impact during installation, and external pressure when buried. |

| Thermal Properties | Vicat Softening Temperature (e.g., ≥75°C) , Heat Resistance | Maintains structural integrity in elevated temperature environments, such as in electrical cabinets or hot climates. |

| Safety & Compliance | Flame Retardancy (Self-Extinguishing) , RoHS Compliance | Critical for electrical safety to prevent the spread of fire. Ensures the material meets international environmental regulations. |

| Processing Performance | Melt Flow Characteristics, Dimensional Stability | Affects how easily the granules can be extruded into complex duct profiles and the final product’s shape consistency. |

More Detailed Guidance

Beyond the core specifications, consider these practical aspects:

-

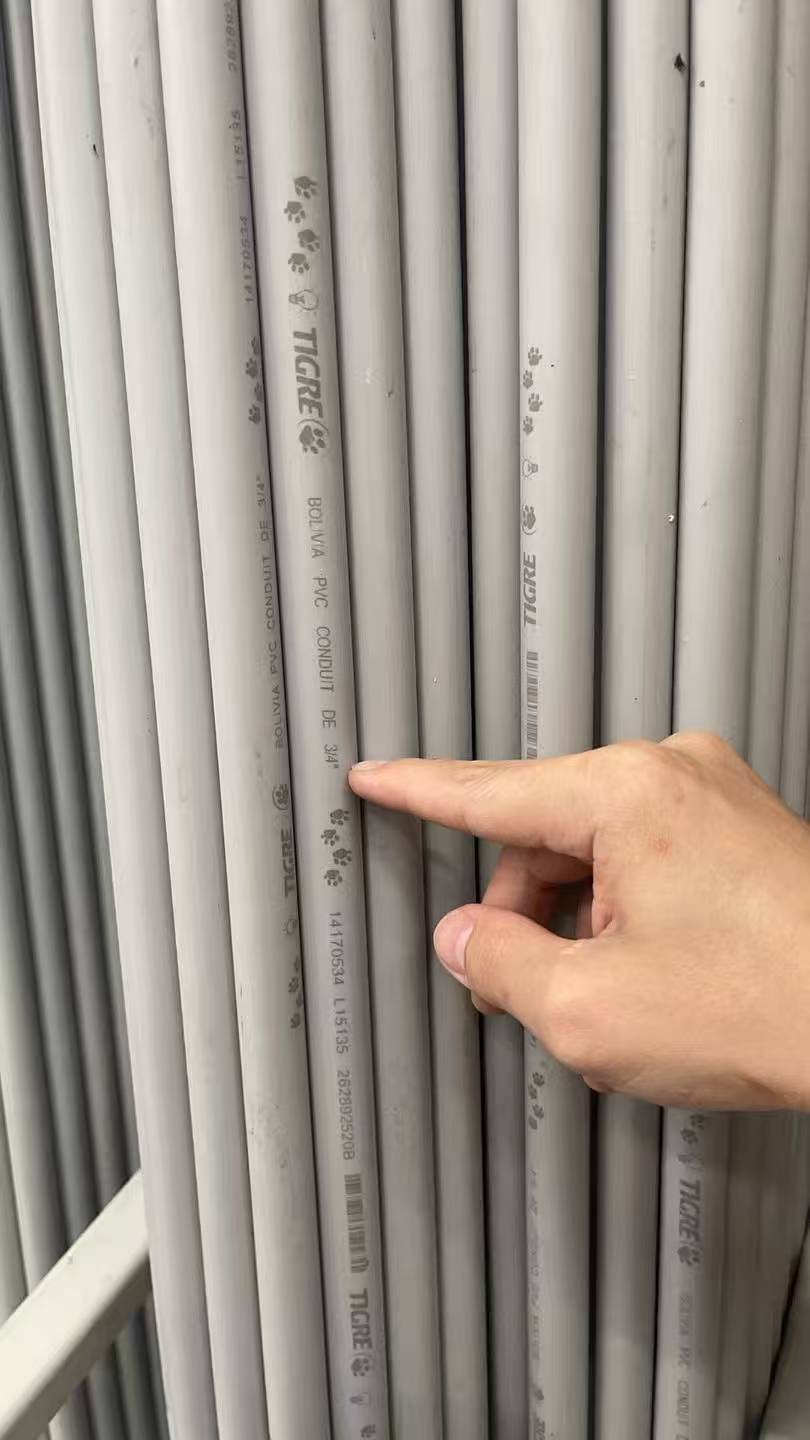

Prioritize Relevant Standards: Ensure the material complies with industry-specific standards. For instance, the DL/T 802.3-2023 standard applies to solid-wall plastic cable conduits made from PVC-U and other materials . Similarly, UL 651 and CSA C22.2 211.2 are key standards for rigid PVC conduit in North America .

-

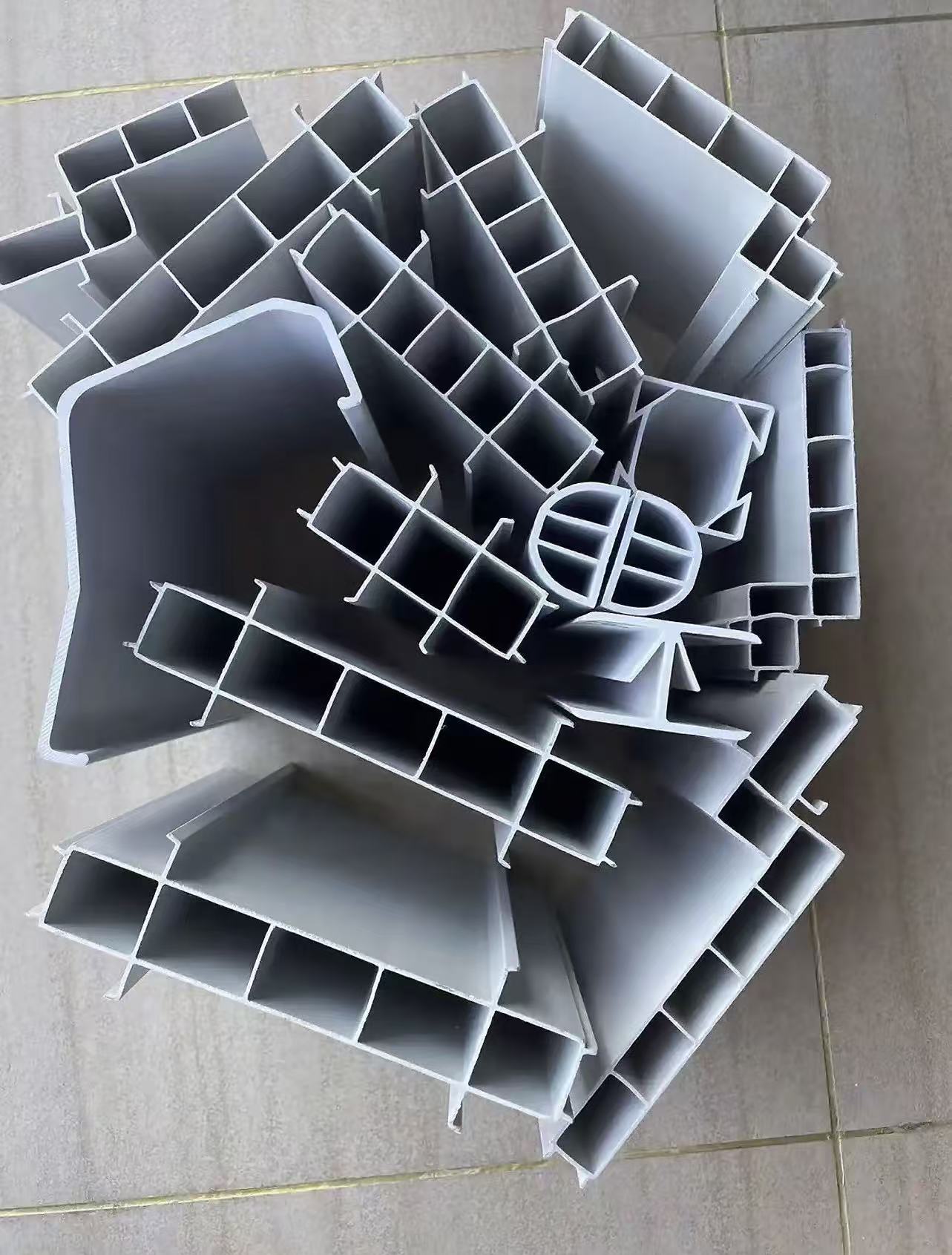

Learn from Existing Products: Review technical data sheets for established wiring duct products. For example, HellermannTyton’s rigid PVC wiring ducts are designed for high-density applications, and Hager Group produces PVC cable routing ducts with specific dimensions, indicating the use of high-quality, consistent PVC compounds .

Application and Selection Advice

When selecting or developing PVC granules for wire ducts, consider the specific application.

-

Match Specifications to Use Case: For underground or outdoor conduits, prioritize high Ring Stiffness, impact resistance, and superior weather/UV resistance. For internal wiring ducts inside control cabinets, focus on flame retardancy (UL94 V-0) and good appearance.

-

Leverage Key Advantages: Well-formulated PVC granules offer excellent balance of strength, durability, and cost-effectiveness. They provide good chemical and corrosion resistance for long service life and are lightweight and easy to install, reducing labor costs.