The table below summarizes the most important specifications to focus on:

| Property | Why It’s Critical for DWV | Key Standards / Requirements |

|---|---|---|

| Impact Resistance | Prevents cracks from handling, installation, or debris during service. | Drop weight impact test (e.g., no failure at -10°C or lower). |

| Ring Stiffness (SN) | Resists deformation from backfill soil loads and ground pressure. | Classified in stiffness classes (e.g., SN2, SN4, SN8) per standards like EN 1401-1. |

| Pipe Stiffness & Crush Resistance | Ensures the pipe won’t collapse under static or dynamic loads. | Defined in standards like ASTM F2390 for DWV pipe. |

| Hydrostatic Burst Resistance | Ensures integrity despite occasional pressure surges or blockages. | Minimum burst pressure specified in standards like ASTM F2390. |

| Dimensional Stability | Prevents joint leaks and system failure from heat-induced shrinkage. | Longitudinal reversion test (low % shrinkage). |

| Heat Resistance | Maintains shape and strength when exposed to hot drainage water. | Vicat Softening Temperature (typically ≥79°C). |

🧪 Specific Formulation Guidance

Achieving the above properties requires a carefully balanced “recipe.” Here are the key components and their roles in a DWV-optimized PVC-U formulation:

-

PVC Resin: Use a resin with a K-value between 65-68 for a good balance of mechanical strength and processability.

-

Impact Modifiers: Essential for toughness. Chlorinated Polyethylene (CPE) or acrylic-based modifiers are commonly added to absorb impact energy and prevent brittle fracture.

-

Heat Stabilizers: Critical to prevent degradation during high-temperature extrusion. Calcium-Zinc (Ca-Zn) systems are the leading environmentally friendly choice, replacing traditional lead-based stabilizers, especially for pipes that may contact wastewater.

-

Lubricants: A balanced system of internal (e.g., stearic acid) and external (e.g., paraffin wax) lubricants ensures smooth processing, good surface finish, and prevents the melt from sticking to equipment.

-

Fillers: Calcium Carbonate (CaCO₃) is the primary filler used to reduce cost and increase stiffness. For non-pressure DWV pipes, higher loadings (up to 40 phr or more) can be used compared to pressure pipes, which improves rigidity and is cost-effective.

-

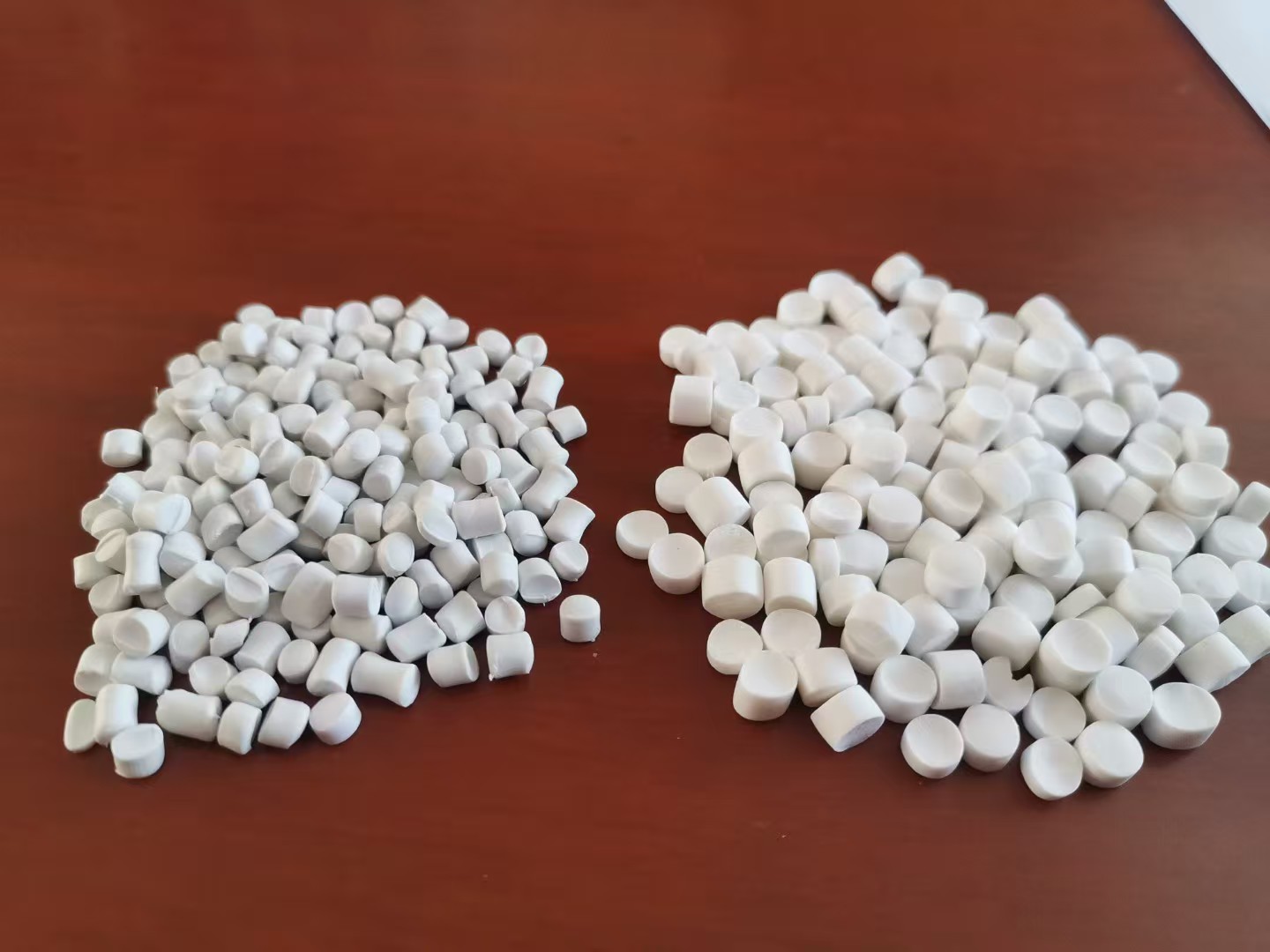

Processing Aids & Pigments: Acrylic-based processing aids promote fusion and improve melt strength. Titanium Dioxide (TiO₂) is the common pigment that provides color (often white/grey for DWV) and acts as a UV protector.

A sample formulation from a patent for underground conduit includes 100 parts PVC resin, 2 parts calcium stearate, 3 parts TiO₂, 2 parts CaCO₃, and 1 part processing aid, highlighting a typical additive structure.