When specifying PVC granules for electric cables, manufacturers require guaranteed performance that ensures safety, longevity, and reliability. Our compounds are engineered to meet these critical demands.

1. Superior Electrical Insulation

The primary function is excellent insulation. Our granules offer high Volume Resistivity and exceptional Dielectric Strength, preventing current leakage and ensuring safe operation even under varying voltage loads.

2. Flame Retardancy & Safety

Safety is non-negotiable. Our formulations are inherently Flame Retardant. They are designed to resist ignition and, in the event of fire, have low smoke emission (Low Smoke Zero Halogen – LSZH options are a major plus) and limit the spread of flames.

3. Thermal Stability

Cables face heat from electrical load and environmental exposure. Our compounds feature high Thermal Stability to prevent degradation during processing (extrusion) and in-service, ensuring longevity and consistent performance.

4. Weatherability & Durability

For outdoor and industrial cables, resistance to UV light, ozone, and moisture is critical. Our additives protect the cable jacket from environmental stress, cracking, and embrittlement.

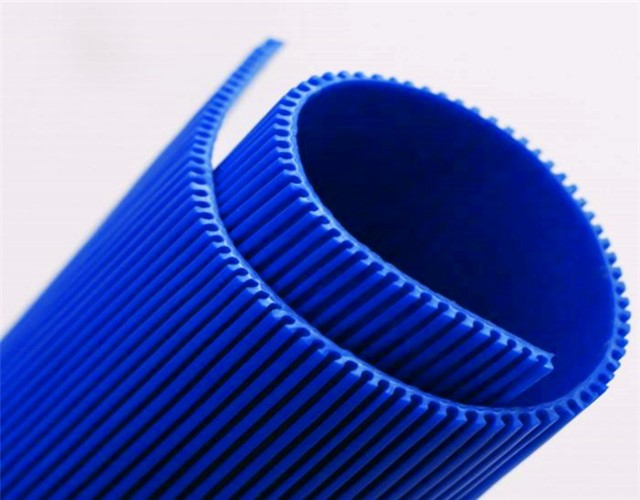

5. Flexibility & Mechanical Strength

A balance is key. The granules must produce cables that are flexible for easy installation yet possess high Tensile Strength and Abrasion Resistance to withstand pulling, bending, and mechanical damage.

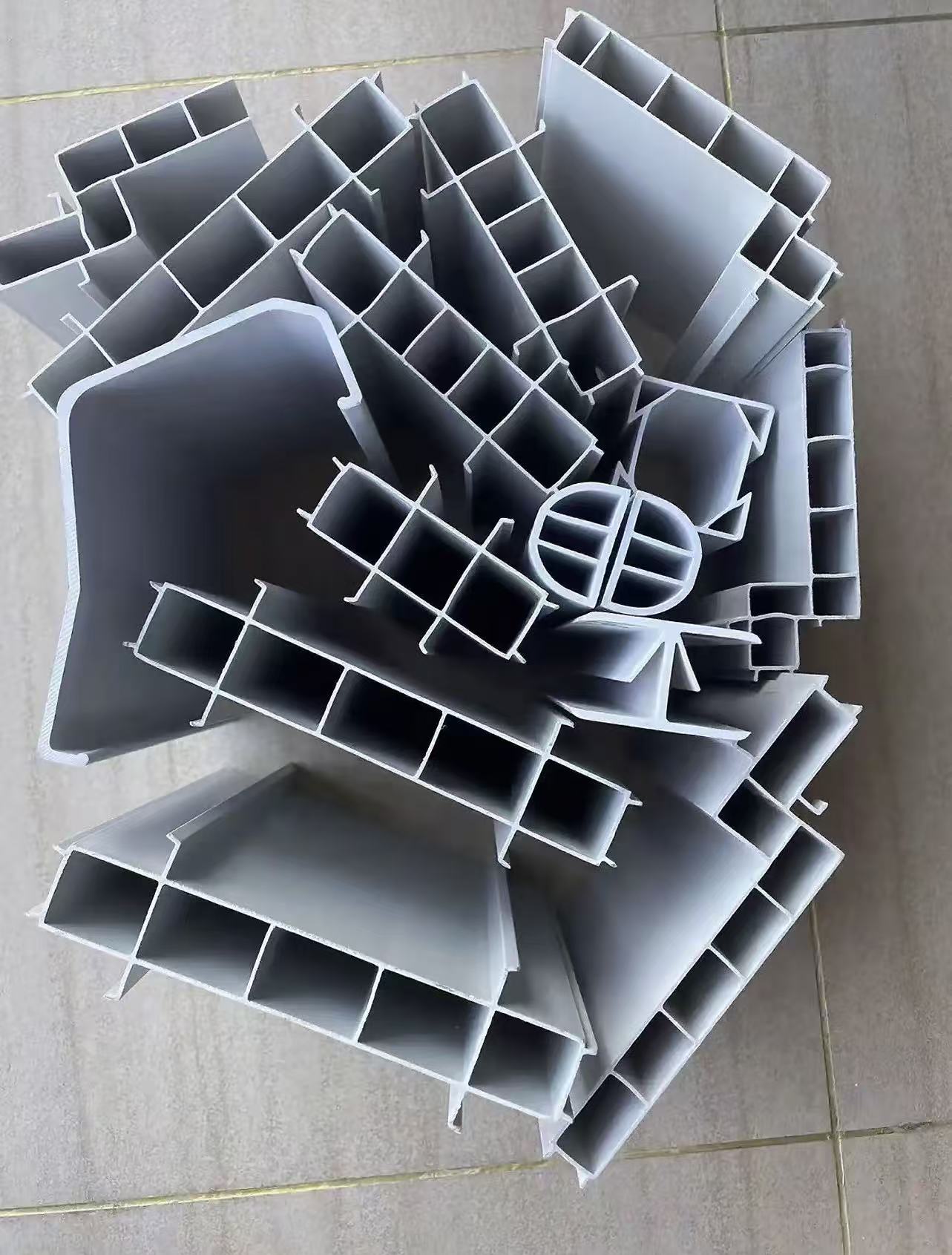

6. Processability

We ensure excellent extrusion characteristics for a smooth, uniform insulation layer, high production speeds, and minimal gel formation, boosting your manufacturing efficiency.

By focusing on these pillars, you assure clients that your PVC granules deliver the safety, performance, and reliability essential for modern cable applications.

Quality Control of PVC Granules

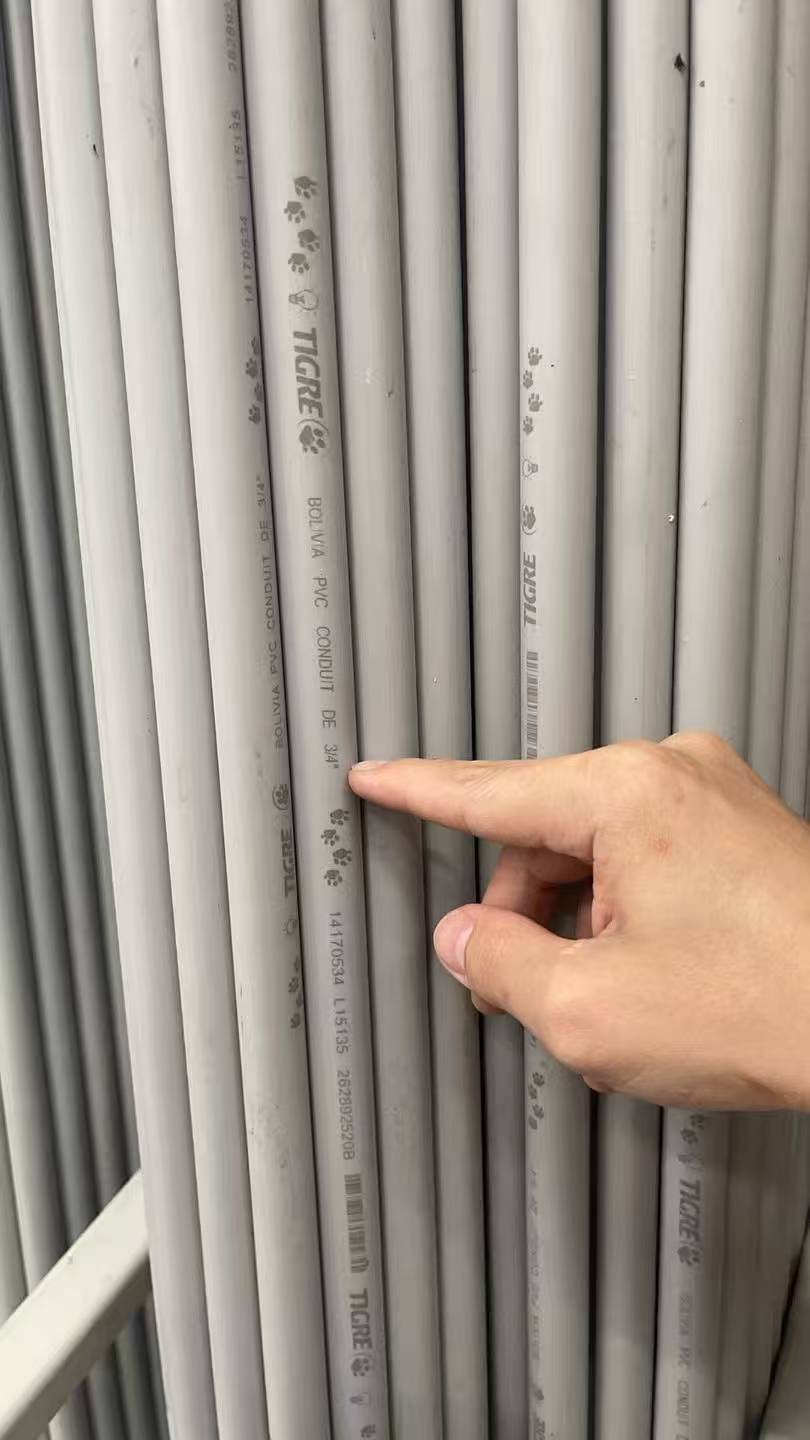

1.Just like our drainage board granules, our cable compounds are based on a proprietary, patented formulation that ensures batch-to-batch consistency and optimal processing.

2.Our granules ensure excellent extrusion performance, leading to a smooth surface finish, higher production speeds, and reduced downtime for your manufacturing lines.

Applications:

Ideal for a wide range of applications, including:

-

Building Wires: Focusing on flame retardancy and safety.

-

Power Cables: Emphasizing thermal stability and insulation.

-

Communication Cables: Highlighting consistent electrical properties.

-

Automotive Cables: Stressing flexibility and heat resistance.