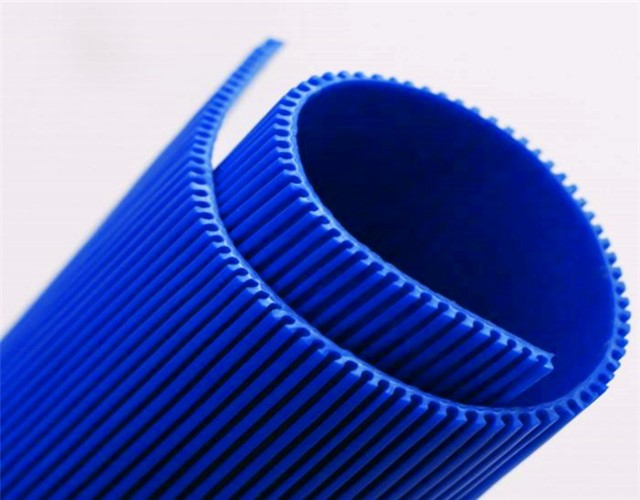

For PVC granules used in column caps and column shoes for mining, the specifications focus on extreme durability, impact resistance, and mandatory mine safety standards. These components are critical for supporting mine roofs and columns.

Key Specifications for Mine Column Cap/Shoe PVC Granules

| Property Category | Key Requirement / Target Value | Importance for Mining Use |

|---|---|---|

| Mechanical Strength | High Impact Strength (e.g., Charpy Notched ≥ 15 kJ/m²), High Compressive Strength | Must withstand enormous and dynamic roof pressures, rock falls, and heavy loads without cracking or deforming. This is the primary function. |

| Flame Retardancy | Must meet strict mining standards (e.g., MSHA, GB/T 16412 or Coal Mine Safety “MA” Certification). UL94 V-0 is a common benchmark. | Non-negotiable for safety. Prevents the component from fueling a fire in underground environments. |

| Anti-Static Property | Surface resistivity typically targeted in the range of 10⁶ – 10⁹ Ω. | Critical for safety to prevent static discharge that could ignite methane or coal dust. |

| Durability & Wear | Excellent Abrasion Resistance and Environmental Stress Crack Resistance (ESCR). | Resists constant wear from rock contact, moisture, and mechanical stress for long service life. |

| Density | Can be adjusted (~1.35 – 1.55 g/cm³) but is generally lower than steel, aiding in handling and installation. | Offers a lightweight advantage over traditional metal components while maintaining strength. |

Product Context & Formulation Focus

-

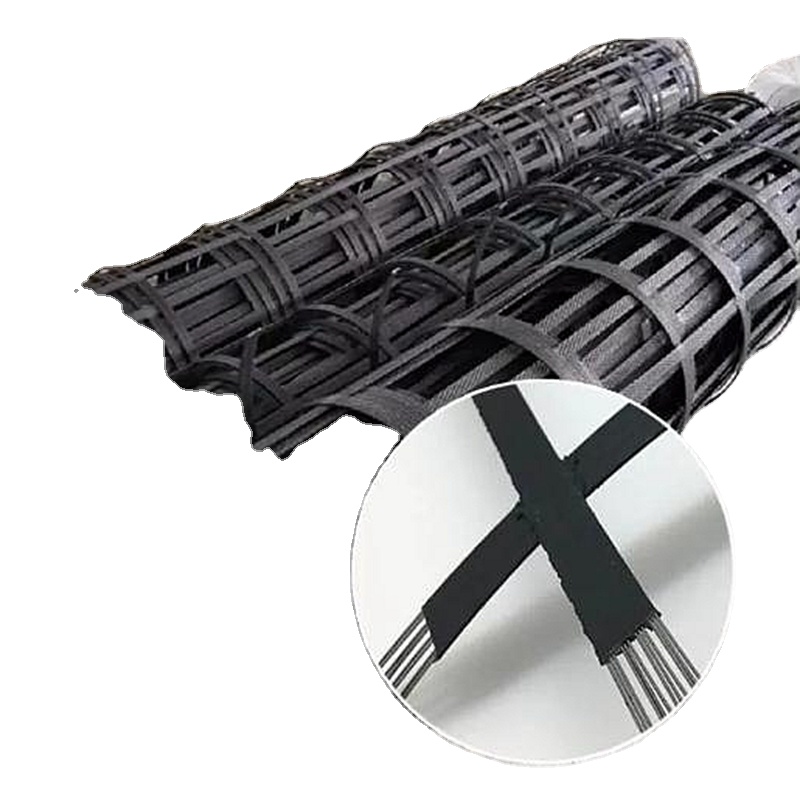

What They Are: Column caps and shoes are critical accessories in mine support systems. They are placed between hydraulic props/columns and the mine roof/floor to distribute pressure, prevent slippage, and protect the prop ends.

-

Why PVC is Used: PVC components offer corrosion resistance, lighter weight for easier transport/installation, and design flexibility compared to traditional metal. The key is formulating the PVC to match or exceed the strength and safety required.

-

Formulation Core: Achieving the above specs requires a high-strength, rigid PVC-U type formulation with key additives:

-

High-impact modifiers (e.g., CPE, acrylic) for toughness.

-

Flame-retardant synergists (e.g., Antimony Trioxide with chlorinated paraffins, or Aluminum Hypophosphite).

-

Anti-static agents (e.g., conductive carbon black, graphene).

-

Reinforcing fillers (e.g., surface-treated calcium carbonate) and robust heat stabilizers (e.g., Calcium-Zinc).

-

Next Steps for Development

Since this is a highly specialized, safety-critical application, I recommend taking these steps:

-

Reference Exact Standards: Obtain and study the specific national or industry standards (like China’s MT/T 113 series for mine safety products) that define the required test methods and performance levels for column caps and shoes.

-

Partner with Testing Institutes: Work with certified laboratories (e.g., coal mine safety product testing centers) early in your development to prototype and test your compounds against the official standards.

-

Secure Certification: For the Chinese market, the Coal Mine Safety Certification (“煤安证” or MA Mark) is typically mandatory for these products to be used in coal mines.

Would you like a deeper breakdown of how specific impact modifiers or flame-retardant systems work in such a high-strength formulation? Contact us!