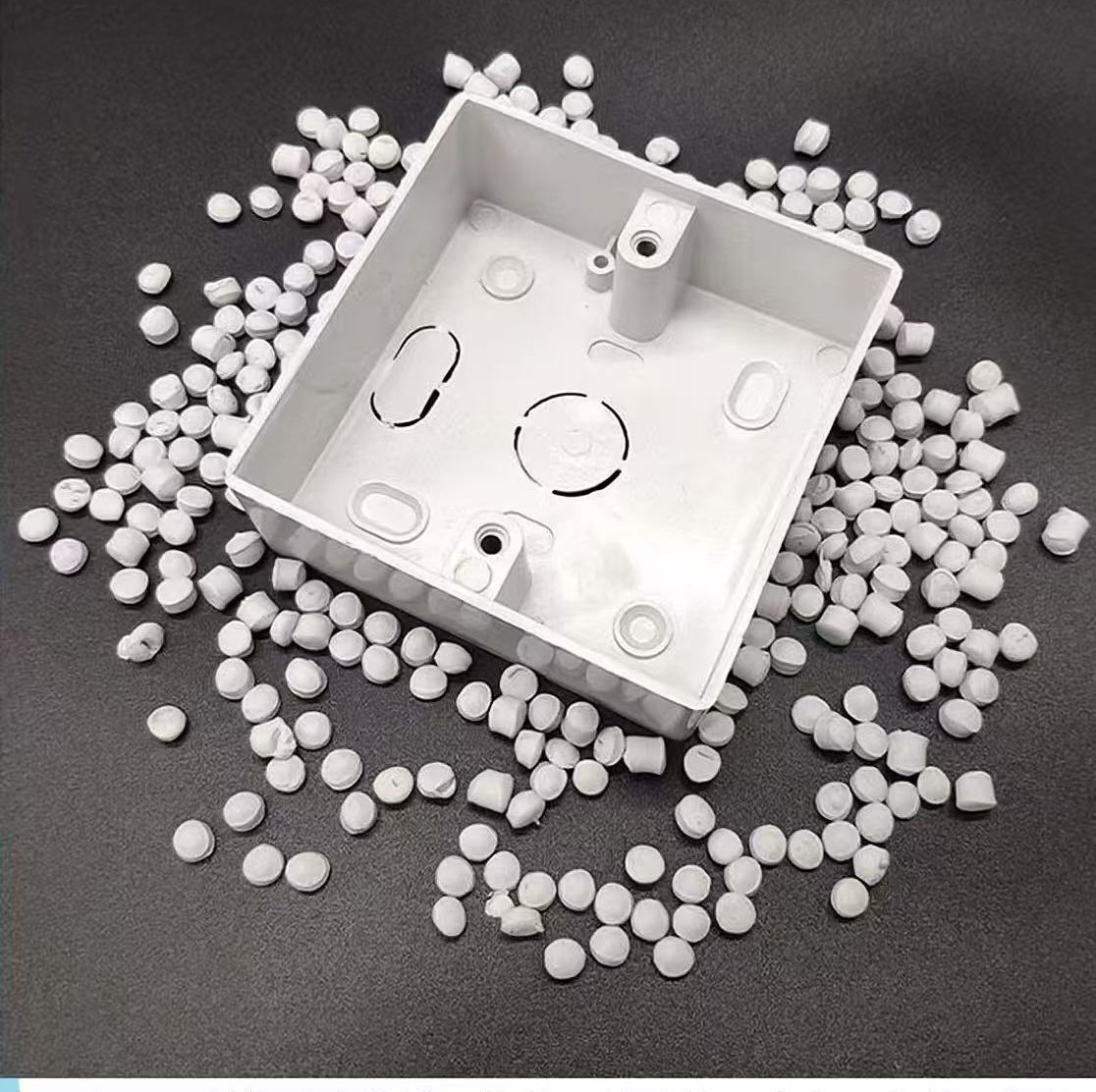

DST provides PVC Granules for brake cable sheathing considering acheiving key performances accordingly.

Key Performance Requirements for Brake Cable Sheathing

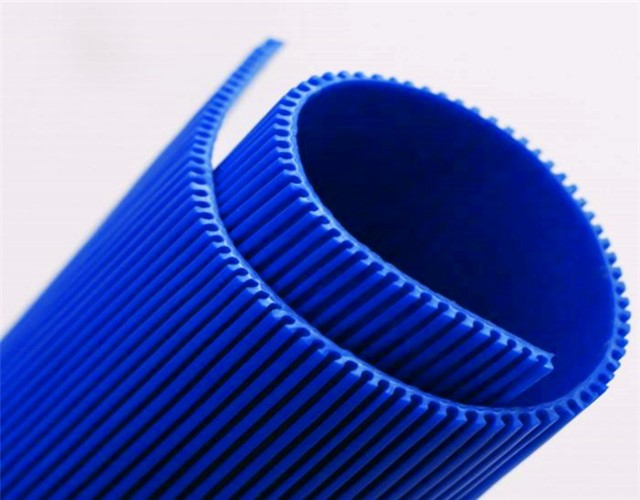

The primary role of the sheathing is to protect the inner cable while allowing for smooth, reliable operation. The key performances required are:

-

Abrasion and Wear Resistance: The sheath must withstand repeated rubbing against housings, guides, and other surfaces without wearing through. High abrasion resistance is a fundamental requirement to ensure long service life.

-

High Mechanical Strength and Toughness: It needs to resist cutting, crushing, and deformation from external forces. Excellent impact resistance is crucial to prevent the sheath from cracking or rupturing under sudden stress .

-

Flexibility and Cold Resistance: The cable must remain pliable in various weather conditions. Good cold bend performance ensures the sheath does not become brittle and crack in low-temperature environments .

-

Weather and UV Resistance: For cables exposed to sunlight and elements, anti-UV properties are essential to prevent degradation, fading, and loss of mechanical strength over time .

-

Low Friction: A low coefficient of friction between the inner cable and the sheath is vital for smooth braking action and reduced wear

Additives for Performance Enhancement

To achieve the above properties, specific additives must be incorporated into the PVC compound. The table below summarizes key additives and their functions:

| Additive Category | Specific Examples | Function in the Compound |

|---|---|---|

| Impact Modifier / Toughener | MABS resin, BOVC resin ; MBS, CPE | Dramatically improves toughness and impact resistance, preventing the sheath from cracking under mechanical shock. |

| Wear Resistance Additive | PVC-specific wear-resistant agent ; Oxidized polyethylene wax | Significantly reduces the coefficient of friction and surface wear, extending the cable’s service life . Also acts as a lubricant . |

| Plasticizer System | TOTM, DIDP | Imparts flexibility and determines the softness of the final product. These specific plasticizers offer good resistance to extraction and heat aging. |

| Stabilizer | Calcium/Zinc composite stabilizer ; Dioctyltin dilaurate | Prevents the thermal degradation of PVC during high-temperature processing (e.g., extrusion) and protects the material from heat and UV during its service life . |

| Lubricant (Internal) | Calcium stearate, zinc stearate; OPE wax | Reduces internal friction during processing, improving melt flow and preventing the material from sticking to equipment . |

| Fillers | Ground calcium carbonate, barium sulfate | Adjusts cost and can improve certain mechanical properties like stiffness. Surface-treated fillers are preferred for better integration and performance. |

A Note on Formulation and Testing

Developing a high-performance PVC compound is a balancing act. The search results emphasize that the optimal selection and proportion of additives are critical . Adding too much of one component can negatively affect another property.

Therefore, while the additives listed above provide a strong starting point, creating a successful formulation for a critical application like brake cables typically involves:

-

Prototype and Lab Testing: Producing small batches and rigorously testing them for key properties like abrasion resistance (e.g., Taber Abrasion test), tensile strength, elongation, and low-temperature flexibility.

-

Performance Validation: Subjecting the final sheathed cable to real-world simulation tests, including cycle fatigue and environmental aging tests.

I hope this detailed breakdown provides a solid technical foundation for your product development. If you require further information on specific test methods or material standards, please feel free to ask.